CNC Turning Service

The JUNYU machine utilizes CNC turning processes to manufacture parts or product prototypes and achieve mass production. It excels in general threading and can efficiently machine round parts such as shafts, worms, and balls.

- Ability to handle complex parts: CNC parts with intricate shapes can be manufactured.

- Surface treatment options: Polished, Anodized, etc.

- Various materials available: Aluminum, Steel, Copper, etc.

- Get your products and parts ready in as fast as 24 hours.

- Certifications: ISO9001:2008, TS16949.

CNC turning process is a precision machining technique that uses a computer-controlled lathe to manufacture cylindrical or round-shaped parts. In this process, a rotating workpiece is fed into a stationary cutting tool to remove material and form the desired shape, including various types of threads. CNC turning demonstrates exceptional efficiency when machining round parts such as shafts, worms, and spheres. The movement of the workpiece and cutting tool is precisely controlled by CNC (Computer Numerical Control) software, ensuring high precision and repeatability in part production. This makes CNC turning particularly suitable for mass production.

CNC Turning Products

Our CNC Turning Capabilities

JUNYU offers a wide range of leading CNC turning services, providing not only high-quality products but also an exceptional service experience. Our professional engineering team will tailor the perfect turning solution based on your needs. To ensure the excellence of our products, we rely on ISO9001:2008 and TS16949 quality system certifications, guaranteeing that each product meets your requirements and offers outstanding durability. We are committed to completing production in the shortest time possible, with delivery as fast as within one day, and swiftly shipping the products to your doorstep.

Fast Tooling

We offer CNC services for fast tooling, ensuring quick delivery of products in a short time.

Rapid Prototyping

We offer large-scale rapid prototyping services with a variety of materials and provide a diverse range of mold options to meet your needs.

Mass Production

Products manufacturing available and quality guaranteed.

Available Materials for CNC Turning

| Aluminum Al6061 / Al6063 / Al6082 / Al7075 / Al5052 / A380, etc. | Steel Alloy Steel, carbon steel etc. | Plastic PET / PVC / ABS / PC / PE / PTFE / POM / PMMA / Nylon / PP / Peek, etc. |

| Cooper C11000 / C12000 / C12000 / C36000, etc. | Stainless Steel Stainless-steel 303 / 304L / 316L / 416 / 440C/ Elmax | Titanium TA0 / TA1 / TA2 / TC4 / TB5, etc. |

CNC turning services are suitable for a variety of materials, including metals and plastics. Different materials require corresponding types of lathes for processing, and depending on the material, the lathe may need special maintenance and safety precautions. The above are common materials that JUNYU can offer, and other materials or custom-sourced options are also available. Once you get a quote, we can start your project immediately.

Surface Finishes for CNC Turning

As Milled – Cutter marks from the CNC turning process will be present, with surface roughness achievable up to Ra 0.8.

Anodized – A thin, hard, non-conductive coating is formed on the surface of aluminum parts. The parts can be anodized in different colors.

Heavy Bead Blast – This treatment removes heavier cutter marks and scratches left by sandpaper, giving the surface a light textured appearance.

Smooth Finish – Typically achieved with 600-grit sandpaper, followed by polishing to achieve a smoother surface.

Powder Coat – A strong, wear-resistant, and corrosion-resistant polymer protective coating is applied to the surface of the part. A variety of colors can be used to achieve the desired aesthetic effect.

Tolerances for CNC Turning

| CNC Turning | ± 0.005″(metal)/±0.05″(plastic) |

Size Limitation for CNC Turning

| Limitation | Parameter (Metric) |

| Max swing diameter | 0.3~3600 mm(0.011~141.732″) |

| Max cutting length | 0.5~1500 mm(0.019~59.055″) |

JUNYU is capable of producing products in various sizes, but there are still certain limitations in CNC machining. Factors such as size may affect the machining process, so we have provided a size limitation table for CNC machining above for your reference. Designers and engineers should fully understand these limitations before designing. Please make sure to review the table carefully before contacting us.

Lowest CNC Service Price

4 factors made our lowest price

1. Advanced and Efficient Machining Equipment

We are equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers. High-speed, high-precision equipment significantly improves machining efficiency, shortens production cycles, and effectively reduces the unit cost.

2. Refined and Optimized Production Processes

With years of industry experience, we continuously optimize our production processes, minimizing material waste and setup time, enhancing overall operational efficiency, and reducing manufacturing costs.

3. Professional Engineering and Technical Team

Our engineers develop optimal machining strategies based on project requirements, selecting the most suitable tools and planning efficient machining paths to improve productivity, reduce errors, and control costs at the source.

4. Stable and Reliable Supply Chain System

We maintain long-term partnerships with premium material suppliers and logistics providers, ensuring low-cost procurement of high-quality raw materials and efficient delivery, further reducing overall production costs.

if you are looking for a low cnc service price,please do not hesitate to get a quote.

Why Choose Junyu for CNC Turning?

Rapid Turnaround – Leveraging state-of-the-art CNC turning technology and advanced tooling, we deliver meticulously crafted components with same-day turnaround.

Extensive Material Selection – Access a broad portfolio of over 100 certified metal and plastic materials, each backed by reliable quality assurance.

High Precision – Deliver exceptional accuracy and uncompromised quality. Dimensional tolerances as tight as ±0.0025 mm (0.000098”) are achievable based on customer specifications.

Competitive Pricing – Backed by a reliable raw material supply chain, we offer fast and cost-effective quotations to meet your budget requirements.

Engineering Support – From single prototypes to high-volume production runs, our team of experienced engineers provides comprehensive technical support at every stage.

Overview of CNC Turning

What’s CNC Turning?

CNC milling and CNC turning are two fundamental types of CNC machining processes, each with distinct methods and applications. CNC milling utilizes rotary cutting tools that approach the stationary workpiece from multiple angles to shape complex geometries. In contrast, CNC turning employs a lathe to rotate the workpiece—typically a rod stock made of metal—while stationary or live tooling machines cylindrical features.

Our CNC turning process is ideal for producing functional prototypes and end-use parts with high precision. It enables the creation of axial and radial holes, flats, grooves, and slots by rotating the material against live tooling. Unlike milling, where the tool moves and the part remains fixed, turning relies on the rotation of the part itself to achieve the desired form.

How Does CNC Turning Work?

CNC lathes operate on a subtractive manufacturing principle to shape raw materials into precise components. Once the “G-code” is generated, the raw bar stock is loaded into the chuck of the lathe’s spindle. As the spindle begins to rotate, the chuck securely holds the workpiece in place. When the spindle reaches its designated speed, a stationary cutting tool is precisely positioned to engage the rotating material, gradually removing excess material until the final geometry is achieved.

CNC turning is ideal for producing rotationally symmetrical parts, enabling rapid material removal while achieving superior surface finishes—often eliminating the need for additional post-processing.

Advantages of CNC Turning

Cylindrical Parts

CNC turning machines are the preferred solution for producing round or cylindrical components. This process ensures fast, precise, and consistent machining, making it ideal for high-efficiency production of symmetrical geometries.

Range of Processes

While CNC turning is primarily used for round or cylindrical parts, it is also highly versatile—capable of performing a wide range of operations such as drilling, boring, threading, knurling, and more.

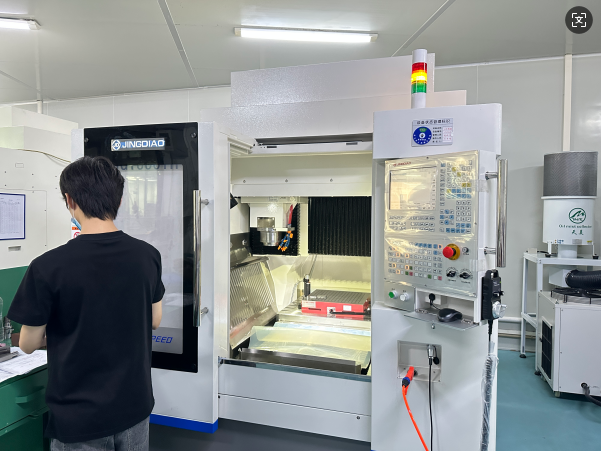

Our CNC Machining Center / CNC Turning Center

Advanced CNC Capabilities

Junyu operates a fleet of over 70 high-precision CNC machines, encompassing a wide range of equipment types. This includes 3-axis, 4-axis, and 5-axis machining centers, drilling and tapping centers, CNC lathes, as well as more than 10 conventional machines such as manual lathes, milling machines, drill presses, and grinders. With this comprehensive setup, our facility supports an annual production capacity of up to one million parts.