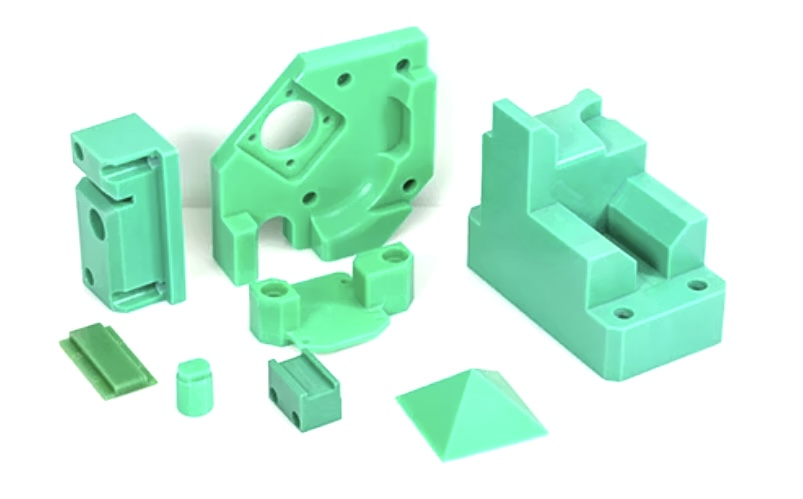

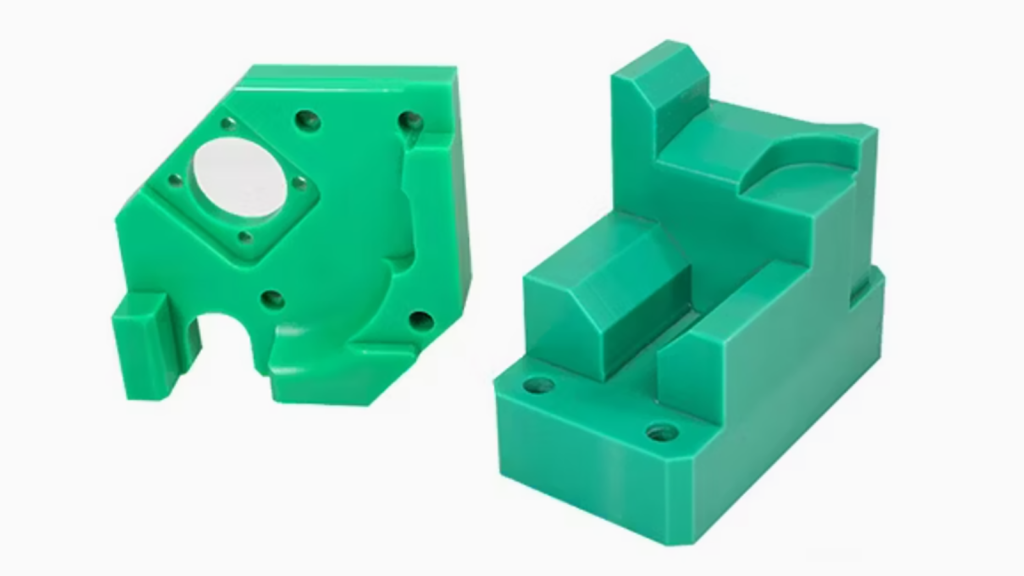

CNC Machining Plastic Parts

As a leading high-quality CNC parts manufacturer in China, JUNYU is equipped with a variety of CNC machining machines, specializing in providing premium CNC plastic parts processing services to customers worldwide. Our rapid plastic parts processing services significantly improve machining efficiency, and our highly competitive pricing is key to our success. Experienced engineers and experts meticulously inspect each plastic part to ensure it meets higher performance standards.

Additionally, we offer excellent custom services for CNC machined plastic parts, catering to the processing requirements of complex part shapes and surface features. Whether you need materials such as ABS, nylon, PEEK, PC, POM, or others, we select the most suitable material based on your part requirements. Simply provide your specifications and drawings, and we will perfectly realize your design. JUNYU is a Chinese CNC manufacturer certified with CE and ISO9001, focusing on providing high-precision, tight-tolerance CNC machined plastic parts.

Why Choose JUNYU’s CNC Machining Plastic Parts Services?

Advanced processing technologies and equipped with high-end, comprehensive CNC machining equipment

Able to provide machining capabilities for a variety of plastic materials

A team of engineers with over 15 years of CNC machining experience, offering high-quality plastic part solutions

Efficient CNC programming, 5-axis machining, and precision production capabilities

CNC Machining Plastic Material parts at JUNYU

CNC Machining ABS Parts – Acrylonitrile Butadiene Styrene (ABS) is a commonly used thermoplastic polymer material. ABS offers excellent impact resistance, heat resistance, and flame retardancy, with transparent color and outstanding strength. ABS parts can be further enhanced in surface quality and performance through post-processing methods such as painting, electroplating, and others.

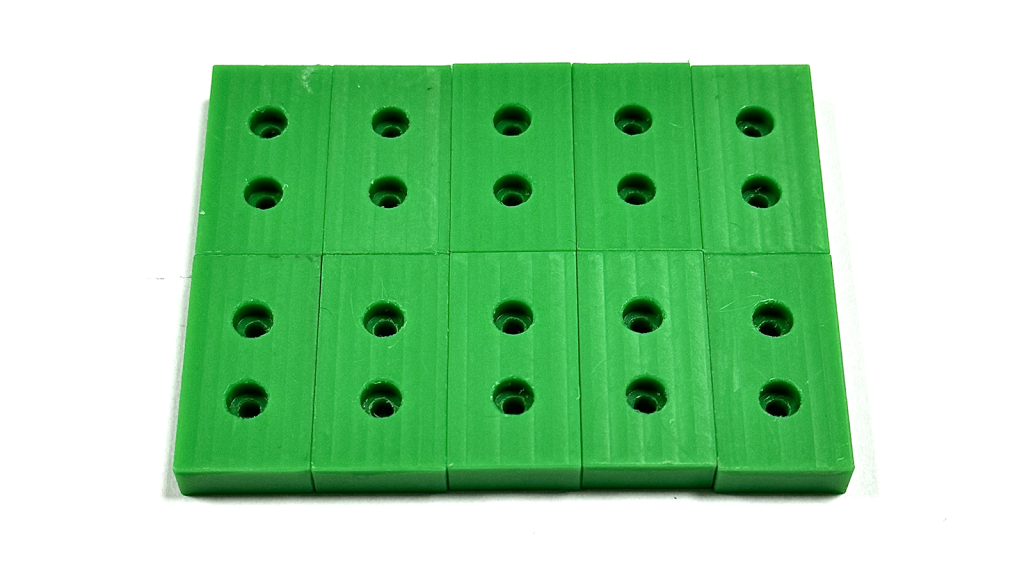

CNC Machining POM Parts (Polyoxymethylene) – POM is a material with excellent creep resistance, high geometric stability, and chemical corrosion resistance, maintaining its superior performance even at low temperatures. Although the high crystallinity of POM results in a high shrinkage rate, this characteristic can be controlled through proper mold design and molding processes. When controlled appropriately, the high crystallinity gives POM good rigidity, hardness, and mechanical strength, meeting the material performance requirements for CNC machining. Additionally, the extremely low coefficient of friction and good geometric stability are key reasons why POM is considered a high-quality CNC machining material. POM can be applied to any CNC machined parts requiring flexibility.

CNC Machining PE Parts – PE (Polyethylene) is a semi-crystalline thermoplastic material that offers high toughness but has low strength and hardness. It has low moisture absorption, high elongation, and excellent chemical corrosion resistance.

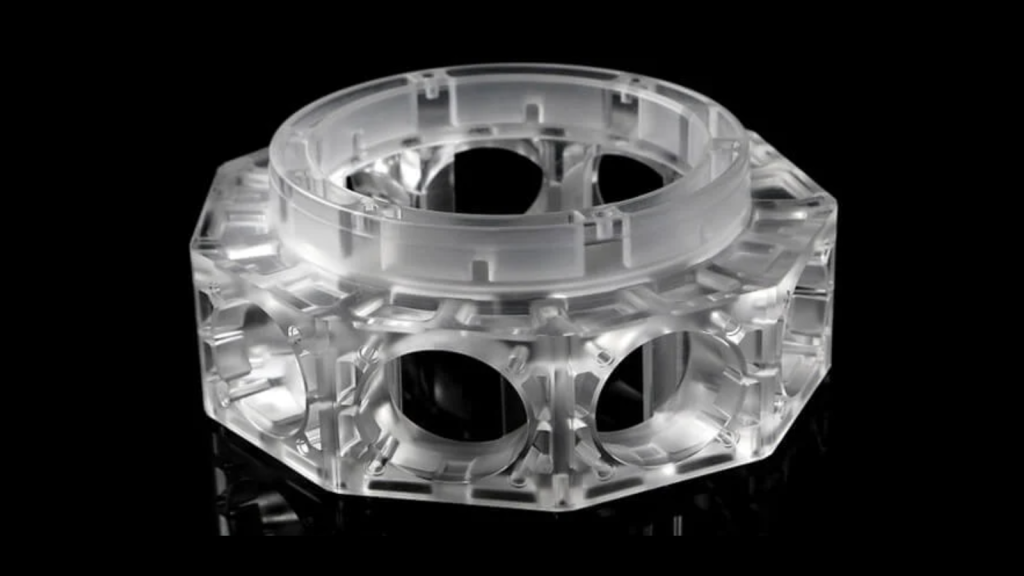

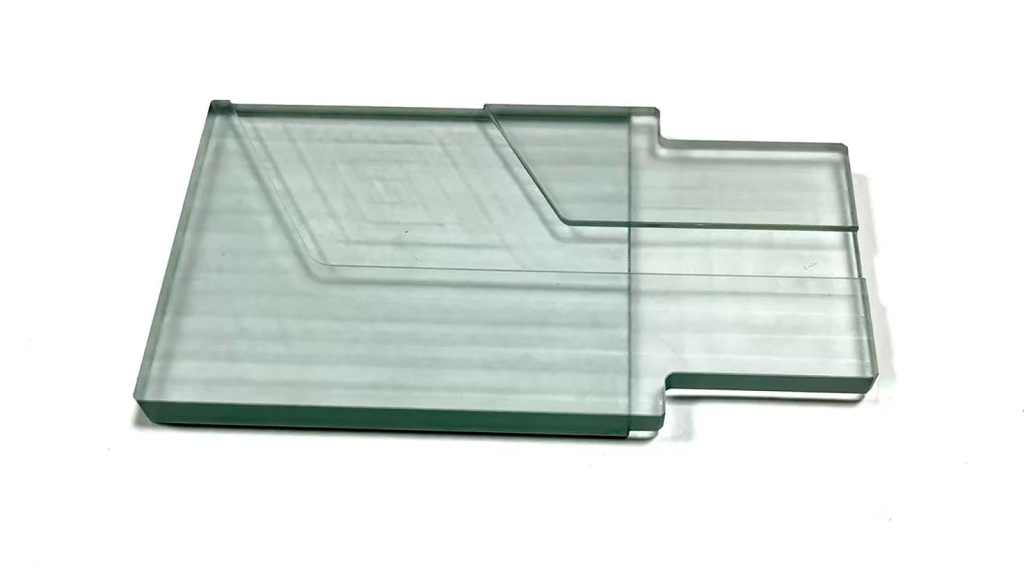

CNC Machining PMMA Parts – Commonly known as acrylic, the chemical name is polymethyl methacrylate (PMMA). This material has good transparency, chemical stability, and weather resistance. It is easy to dye, process, and has an attractive appearance. It is transparent like glass but has the toughness and machinability of plastic, which is why it is referred to as “organic glass.”

CNC Machining PA (Polyamide or Nylon) Parts – Nylon is an engineering plastic with excellent overall properties. Its characteristics include high strength, good toughness, wear resistance, chemical corrosion resistance, as well as excellent electrical insulation and certain heat resistance. Although nylon exhibits moisture absorption, which may affect its dimensional stability and mechanical properties to some extent, proper drying treatment and design optimization can effectively mitigate this impact. Therefore, nylon is widely used in the manufacturing of mechanical structural parts and maintainable components, serving as a prime example of a “universal grade” material.

CNC Machining PC (Polycarbonate) Parts – Polycarbonate (PC) is a high molecular weight polymer that contains carbonate groups in its molecular chain. This structure gives PC materials a range of unique properties, such as excellent impact resistance, transparency, and thermal stability. The three main application areas of PC engineering plastics are the electronics and electrical industry, automotive industry, and construction and decoration industry, followed by industrial machinery parts, optical disc packaging, computers and other office equipment, medical and healthcare, films, leisure, and protective equipment, etc.

CNC Machining PEEK (Polyetheretherketone) Parts – Polyetheretherketone (PEEK) resin is a special engineering plastic with excellent performance, offering unique advantages over other specialty engineering plastics. PEEK features outstanding high-temperature resistance, strong chemical stability, and good overall mechanical properties. These exceptional characteristics have led to PEEK’s widespread application in many high-end fields, such as aerospace, automotive, electronics, and healthcare, making it a typical high-performance engineering plastic. Additionally, PEEK also possesses flame retardancy, peel resistance, and wear resistance, making it widely used in high-end machinery, nuclear engineering, and aerospace industries.

CNC Machining PTFE (Polytetrafluoroethylene or Teflon) Parts – Polytetrafluoroethylene (PTFE), also known as Teflon, is a synthetic polymer material synthesized from tetrafluoroethylene monomers through a polymerization reaction initiated by a catalyst. It offers excellent resistance to acids, alkalis, and various organic solvents, being almost insoluble in all solvents. At the same time, PTFE has outstanding high-temperature resistance, and its friction coefficient is very low, making it suitable as a lubrication material. It has also become an ideal coating for non-stick cookware and water management systems.

CNC Machining PVC (Polyvinyl Chloride) Parts – Polyvinyl chloride (also known as PVC) is a polymer synthesized from vinyl chloride monomers through free radical polymerization, under the action of initiators such as peroxides and azo compounds, or through exposure to light and heat. Vinyl chloride homopolymers and vinyl chloride copolymers are collectively referred to as vinyl chloride resins. PVC was once the world’s largest produced general-purpose plastic and has a wide range of applications. It is widely used in building materials, industrial products, daily necessities, flooring leather, floor tiles, artificial leather, pipes, wires and cables, packaging films, bottles, foaming materials, sealing materials, fibers, etc.

The Most Reputable Plastic Parts CNC Machining Manufacturer in China

JUNYU is one of the most reliable plastic parts CNC machining manufacturers in China, with a professional engineering team and skilled operators with over 15 years of experience. We are equipped with more than 100 advanced CNC machining centers, capable of efficiently completing CNC machining for ABS and various plastics. We handle a wide range of materials, including ABS, PET, PVC, PC, PE, PTFE, POM, PMMA, Nylon, PP, and PEEK. If you are looking for a reliable manufacturer for plastic CNC machining services, please feel free to contact us.