CNC Turning Steel Parts

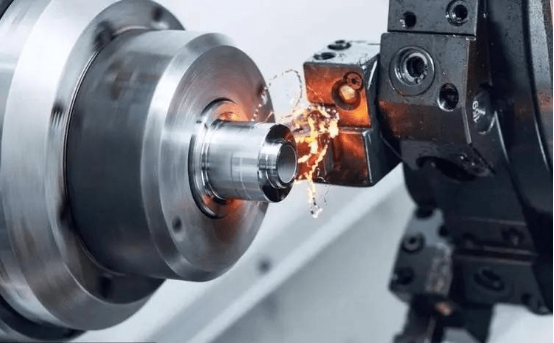

Steel is the most commonly used material in manufacturing and has long been the material of choice for machining parts. In CNC machining, CNC turning is the most widely used process for manufacturing custom rigid parts.

Why Choose JUNYU CNC Turning Steel?

At JUNYU, we have extensive knowledge and expertise in CNC turning, and our years of machining experience give us full confidence in machining CNC steel parts.

We have a wide variety of lathes, offering many options to our customers, and we collaborate effectively with subcontractor partners. This enables us to produce both complex assemblies and simple parts.

Like CNC milling, CNC turning is a machining process that involves chip removal. Our well-maintained and updated equipment allows us to consistently deliver high-quality turned workpieces. We work with materials such as steel, aluminum, stainless steel, plastic, brass, and copper.

CNC Turning for Steel Materials Parts

Steel SKD11

SKD11 is a high-carbon, high-chromium alloy tool steel that belongs to the cold work die steel category. It is widely used for making precision dies and tools due to its excellent wear resistance, toughness, and hardenability. SKD11 is equivalent to D2 (AISI), X153CrMoV12 (DIN), and 1.2379 (Werkstoff) in other international standards.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.1900 (Tensile Strength) Approx. 1500 (Yield Strength) | Approx. 210-215 | Approx. 10-12 | Annealed: ≤255 HB Quenched & Tempered: ≥60 HRC (Approx. 580-620 HB when converted to Brinell) | 7.85 |

Steel SKH51

SKH51 is a high-speed tool steel that belongs to the M2 grade in the AISI standard. It is widely used in cutting tools due to its excellent wear resistance, high hardness, and good toughness. SKH51 retains its hardness even at elevated temperatures, making it ideal for high-speed

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.2300 (Tensile Strength) Approx.1800 (Yield Strength) | Approx. 210-220 | Approx. 8-10 | Annealed: ≤255 HB Quenched & Tempered: ≥63 HRC (Approx. 620-650 HB when converted to Brinell) | 8.0 |

Steel DC53

DC53 is a high-performance cold work tool steel that is an improved version of SKD11 (D2). It offers superior toughness, wear resistance, and machinability, making it ideal for precision dies, cutting tools, and high-stress mold components. DC53 overcomes the weaknesses of SKD11, such as brittleness and chipping, by modifying its alloy composition and heat treatment properties.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx. 2400 (Tensile Strength)Approx. 2100 (Yield Strength) | Approx. 210-215 | Approx. 12-15 | Annealed: ≤255 HB Quenched & Tempered: ≥62 HRC (Approx. 600-630 HB when converted to Brinell) | 7.85 |

Steel SKS3

SKS3 is a cold work tool steel known for its high toughness, good wear resistance, and excellent machinability. It belongs to the same category as AISI O1 (Oil-Hardening Steel) and DIN 1.2510, making it a widely used material for cutting tools, punches, dies, and knives.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.780-1100 (Tensile Strength)Approx.600-850 (Yield Strength) | Approx. 190-210 | Approx. 10-20 | Annealed: ≤229 HB Quenched & Tempered: ≥55 HRC (Approx. 530-580 HB when converted to Brinell) | 7.7-7.8 |

Steel S136

S136 is a high-purity stainless tool steel developed for plastic mold applications requiring excellent corrosion resistance, polishability, and wear resistance. It is widely used in the medical, optical, and food packaging industries, where high surface quality and durability are critical.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.1350 (Tensile Strength) Approx. 1100(Yield Strength) | Approx. 210 | Approx. 12-15 | Annealed: ≤215 HB Quenched & Tempered: ≥50 HRC (Approx. 480-520 HB when converted to Brinell) | 7.8 |

Steel Stavax

STAVAX is a premium-grade stainless tool steel developed by Böhler-Uddeholm, widely recognized for its exceptional corrosion resistance, polishability, and wear resistance. It is a modified version of AISI 420 tool steel, designed specifically for plastic injection molds and other applications requiring a high-gloss surface finish.

| Tensile Strength, Yield Strength (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.1400 (Tensile Strength) Approx. 1200 (Yield Strength) | Approx. 210 | Approx. 12-15 | Annealed: ≤215 HB Precipitation Hardened: 50-52 HRC (Approx. 480-520 HB when converted to Brinell) | 7.78 |

Advantages of CNC Turning Steel Parts

CNC turning is an automated process that significantly improves work efficiency.

Compared to manual turning, it generally results in lower error rates and higher part quality.

CNC turning is ideal for producing small and medium-sized parts, typically ranging from 50 to 1000 units. Additionally, it helps save labor costs, leading to an overall reduction in part costs.

What is CNC Turning?

Turning is a machining process, and CNC (Computer Numerical Control) turning is a technique that uses a numerical control system to control the rotation of the lathe spindle and the movement of the tool to machine cylindrical, disc-shaped, and other rotary workpieces. Compared to boring and milling, turning is the most common machining method in modern manufacturing.

In the turning process, the main challenges are related to chip formation and machining costs. Proper control of chip flow and chip breaking is crucial, as it ensures that the material being removed is efficiently evacuated from the machining area. Additionally, controlling chip breakage helps remove cutting heat from the process, optimizing performance and extending tool life.

Materials Finishes

The finish of steel is similar to that of stainless steel, typically shiny in appearance but slightly darker than aluminum alloys. CNC-turned steel parts can be further processed through media blasting or electropolishing to achieve a variety of surface finishes.

Process Characteristics of CNC Turning

- High Precision, Consistency, and Complex Contour Machining Capability: No manual feeding is required, ensuring strong dimensional stability and high part consistency in mass production, making it suitable for precision parts (such as aerospace shafts and medical device components).

- Automation and Multi-Process Integration: Multiple processes can be completed in one clamping, reducing errors from multiple clamping. The program can automatically change tools, combined with spindle speed changes and feed rate adjustments, enabling efficient processing of complex parts.

- Flexibility and Programmability: Different-shaped parts can be processed without changing hardware, making it suitable for small-batch, multi-variety production (e.g., prototype production and customized parts).

- Efficiency and Intelligence: Production efficiency is 3-5 times higher compared to traditional lathes.

- Wide Material Compatibility: Can process various materials such as steel, cast iron, aluminum alloys, titanium alloys, and plastics. Different tools (e.g., ceramic tools, carbide tools) are selected to match the material properties.

- Part Types: Typical parts include rotational workpieces such as shafts (e.g., motor shafts, lead screws), discs (e.g., flanges, gear blanks), sleeves (e.g., bearing sleeves), and threaded parts (e.g., pipe threads, trapezoidal threads).

Application of JUNYU CNC Turning Steel Parts

Medical Instruments

Airplane

Military

Fishing

Auto Industry

Electrical Appliances

Communication Equipment

Machine Made

Industrial Equipment

Try JUNYU Machine Out Now In Just A Few Steps

Upload your CAD files

Send us your FDF file drawings and CAD or 3D files.

Receive your price

You will receive the quote within a few hours.

Order your parts online

You confirm the order and make the payment through the secure payment platform.

Receive your parts

In a short period of time, the parts you ordered will be delivered directly to your shipping address. You can track your package anytime through your personal account.