Wire EDM Service

JUNYU utilizes advanced WEDM (Wire Electrical Discharge Machining) technology to process a wide range of precision metal parts. You need to provide the CAD files of your product, and we will efficiently handle the rest—ensuring fast and seamless delivery from design to finished part.

- High Precision Machining: Standard dimensional tolerance up to ±0.0001mm

- Wide Material Compatibility: Supports commonly used metals such as aluminum, steel, tungsten steel, and copper

- Rapid Delivery: Products and parts can be delivered in as fast as 24 hours

- Comprehensive Certifications: Certified under ISO9001:2008 and TS16949 quality management systems

WEDM (Wire Electrical Discharge Machining) is a high-precision cutting technology that uses the principle of electrical discharge erosion to process conductive materials.

It is particularly suitable for machining complex contours, high-hardness materials, and precision components, and is widely used in industries such as mold making, aerospace, and precision part manufacturing.

As a leading manufacturer of precision molds and components, JUNYU is equipped with a wide range of high-precision machinery, including Wire EDM machines, precision EDM equipment, CNC machining centers, and optical profile grinders. We are fully capable of meeting our clients’ strict requirements for high-precision and high-quality machining.

Our Wire EDM Equipment List

| Brand | Model | Origin | Qty | Min. Wire Ø | Tolerance | (Ra) | Travel (X × Y × Z) |

| AgieCharmilles | CUT2000 | Switzerland | 2 | 0.03 mm | ±0.001 mm | Ra 0.03um | 350 × 250 × 256 mm |

| Sodick Oil | AP250 | Japan | 2 | 0.03 mm | ±0.001 mm | Ra 0.03um | 250 × 150 × 120 mm |

| Sodick | AQ400LS | Japan | 1 | 0.10 mm | ±0.002 mm | Ra 0.15um | 400 × 300 × 250 mm |

| Sodick | ALN400GS | Japan | 1 | 0.10 mm | ±0.002 mm | Ra 0.15um | 400 × 300 × 250 mm |

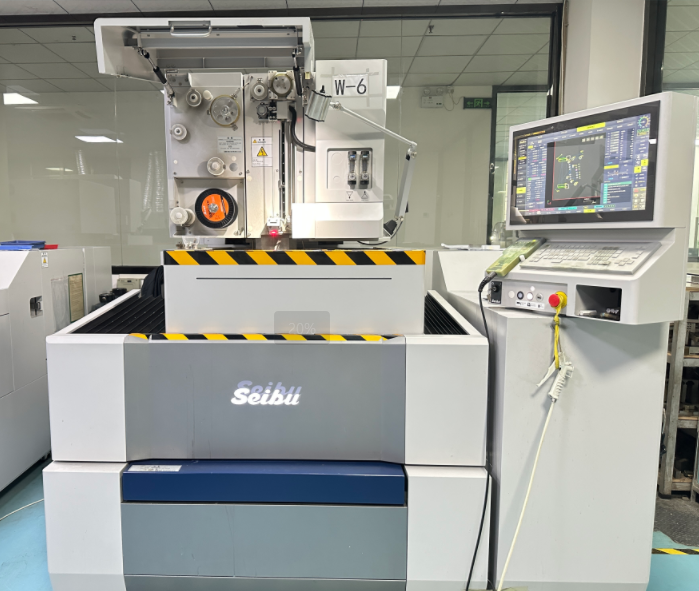

| Seibu | M50A | Japan | 2 | 0.10 mm | ±0.002 mm | Ra 0.15um | 500 × 350 × 310 mm |

| Seibu | M50B | Japan | 2 | 0.10 mm | ±0.002 mm | Ra 0.15um | 500 × 350 × 310 mm |

| Seibu | M50HP | Japan | 2 | 0.10 mm | ±0.002 mm | Ra 0.15um | 500 × 400 × 310 mm |

| Seibu | M35HP | Japan | 2 | 0.10 mm | ±0.002 mm | Ra 0.15um | 350 × 300 × 230 mm |

Our Capabilities of Wire EDM

1.Machining Accuracy: Up to ±0.001 mm

2.Surface Finish: Achievable up to Ra 0.03

3.Minimum Wire Diameter: Ø0.03 mm

4.Processable Materials: Hardened steel, tungsten carbide, titanium alloys, copper, aluminum, magnetic steel, semiconductor silicon wafers, high-temperature alloys (e.g., Inconel), etc.

5.Maximum Machining Thickness: 250 mm

6.Customized Services: Support for small-batch prototyping (1–10 pieces) and large-scale production; capable of processing based on customer drawings or joint development.

7.Inspection Capabilities: Equipped with ZEISS coordinate measuring machine (CMM), NIKON vision measurement system, and NIKON height gauge to ensure dimensional and geometric tolerance accuracy.

Wire EDM Processing Overview

Wire EDM (Electrical Discharge Machining) is a machining process that uses a continuously moving thin metal wire (such as molybdenum or copper) as an electrode. Metal is eroded from the workpiece through pulse discharges between the wire and the workpiece, achieving precise cutting. The key process elements are as follows:

I. Machining Principle

The CNC system controls the electrode wire to move along a programmed path while applying pulsed voltage between the wire and the workpiece. Discharge erosion occurs, gradually removing material to shape the part. This process is a type of non-traditional machining known as EDM (Electrical Discharge Machining).

II. Main Process Steps

1. Workpiece Preparation

- Deburr and flatten the raw material to ensure a smooth clamping surface.

- Determine the threading hole position (usually inside the part contour to prevent cracking at the start point).

2. Machine Setup

- Install the electrode wire (molybdenum or copper, diameter 0.03–0.25 mm) and adjust its tension and verticality.

- Clamp the workpiece and align precisely using a dial indicator to ensure positional accuracy.

3. Programming & Parameter Setting

- Use CAD/CAM software to draw the geometry and generate the NC code (e.g., 3B, G-code).

- Set discharge parameters: pulse width, interval, current, voltage, etc., which affect cutting speed and surface roughness.

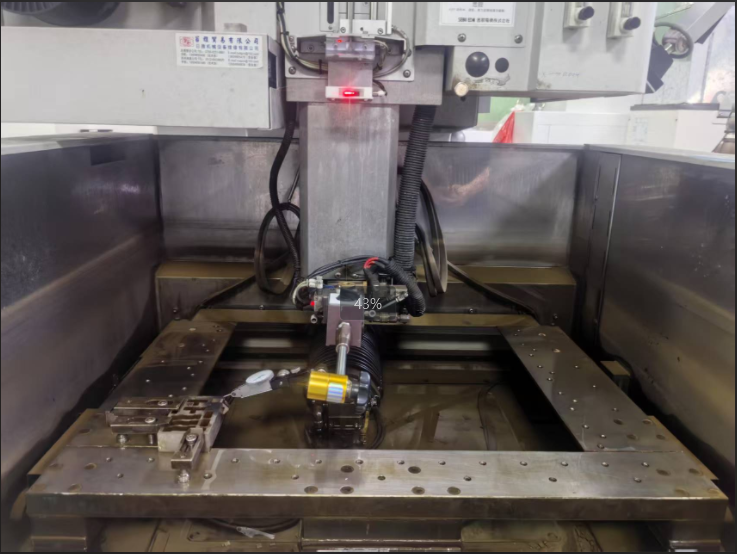

4. Cutting Process

- Introduce working fluid (emulsion or deionized water) for cooling and debris removal.

- Start the machine; the wire moves along the programmed path to cut the workpiece layer by layer.

5. Post-processing

- Deburr and clean the finished part.

- Inspect dimensions and surface quality (accuracy up to ±0.001 mm, surface roughness Ra 0.03–2.5).

Key Characteristics of Wire EDM (Electrical Discharge Machining)

1. Main Advantages

- High Precision

- Tolerances can reach up to ±0.001 mm, ideal for high-accuracy molds and precision components.

- Excellent Surface Finish

- Surface roughness as fine as Ra 0.03 can be achieved, often eliminating the need for secondary polishing or finishing.

- Complex Geometry Capability

- Easily handles intricate shapes such as narrow slots, sharp internal corners, fine contours, and complex profiles that are difficult to achieve with traditional machining.

- Suitable for Hard Materials

- Effectively processes hardened steels, tungsten carbide, titanium alloys, and high-temperature alloys like Inconel.

- No Cutting Force or Deformation

- As a non-contact process, it introduces no mechanical stress to the workpiece, making it ideal for thin-walled or delicate parts.

- Low Electrode Consumption

- Uses standard copper or molybdenum wire electrodes with minimal wear, reducing material and tooling costs.

2. Limitations

- Conductive Materials Only

- The process requires electrically conductive materials and cannot be used for ceramics, plastics, or insulators.

- Lower Processing Efficiency

- Slower cutting speeds compared to milling or laser cutting, especially for thick materials or large-volume production.

- High Equipment and Maintenance Costs

- Wire EDM machines are expensive and require regular, precise maintenance for optimal performance.

- Minimum Kerf Width Constraints

- The narrowest achievable cut width depends on the diameter of the wire electrode (typically 0.03 mm to 0.25 mm), which may limit extremely fine features.

Applications of Wire EDM (WEDM) Components

Wire EDM components are widely used across various industries due to their high precision and capability to process complex geometries, covering applications from precision mold inserts to high-end functional parts.

1. Mold Manufacturing

- Stamping Dies: Punch and die inserts, cutting edges, and complex contours

- Injection Molds: Sliders, cores, and precision inserts

- Die Casting Molds: Wear-resistant and high-temperature components

2. Precision Mechanical Parts

- Gears and Worm Wheels: Non-circular gears, micro gears, high-precision worm drives (e.g., instrumentation components)

- EDM Electrodes and Fixtures: Custom-shaped electrodes and precision positioning components for tooling

- Precision Fixtures and Assembly Blocks: High-accuracy locating and mounting parts for complex assemblies

3. Electronics and Semiconductor Industry

- Precision Connectors and Terminals, lead frames for ICs

- Microstructure Processing: Narrow slots and micro holes for electronic packaging

- Photovoltaics: Cutting and precision machining of silicon wafers and substrates

4. Aerospace and Defense

- Turbine Blade Root Slots and Cooling Holes

- Structural Brackets and Alignment Components

- High-Temperature Alloys: Components made from titanium, Inconel, etc.

- Aircraft Locking Mechanisms and Custom Fasteners

5. Medical Devices

- Minimally Invasive Surgical Tools

- Implants: Titanium and stainless-steel implantable parts

- Orthopedic Devices: Precision instruments and structural components

- Micro Components: Compliant with biocompatibility and miniaturization requirements

6. Automotive and General Machinery

- Precision Gears, Bushings, Locating Pins

- Fuel Injector Parts and Fuel System Components

- Transmission Parts: Precision internal transmission structures

- Hydraulic and Pneumatic Control Elements

7. Precision Engineering and R&D

- Custom Prototypes with Complex Geometries

- MEMS (Micro-Electro-Mechanical Systems) Components

- Inspection Fixtures and Alignment Tools

- Small-Batch Production for Validation and Testing

Materials for EDM

JUNYU’s Wire EDM (WEDM) services efficiently process a wide range of conductive metal materials, meeting the demands of precision component manufacturing.

Tool steels

Steel 1018, steel 4130, steel 4140, Steel 4140PH, steel A36, Steel 4340, SKD11,DC53, SKS3,SKH9,SKH51,45#,1.2379etc.

Stainless steels

Stainless steel 303, stainless steel 304L, stainless steel 316L, stainless steel 416, stainless steel 440c.STAVAX

Aluminum alloys

Alloys 6061, 7075, 7050, 2024, 5052, 6063, MIC6

Cooper

Cooper 110, cooper c10100

Titanium

Titanium TA0 / TA1 / TA2 / TC4 / TB5, etc.

Brass

Brass HPb63 / HPb62 / HPb61 / HPb59 / H59 / H68 / H80 / H90, etc.

Why Choose Our Wire EDM Service?

Here’s why our Wire EDM (WEDM) service stands out:

1.Ultra-High Precision

Achieve dimensional tolerances up to ±0.001 mm and surface roughness as fine as Ra 0.03 μm—ideal for demanding applications.

2.Advanced Equipment

Equipped with top-tier machines from AgieCharmilles, Sodick, and Seibu, supporting wire diameters as small as 0.03 mm.

3.Wide Material Compatibility

Capable of processing hardened steel, tungsten carbide, titanium alloys, Inconel, copper, aluminum, and other conductive metals.

4.Complex Geometry Machining

Easily handle fine features, narrow kerfs, sharp internal corners, taper cuts (up to ±30°), and intricate contours.

5.Strict Quality Control

In-house inspection with ZEISS CMM, NIKON optical systems, and height gauges ensures dimensional and geometric accuracy.

6.Fast Turnaround

Efficient setup and streamlined production allow delivery in as fast as 24 hours for urgent projects.

7.Flexible Production Support

From one-off prototypes to high-volume runs, we offer full support for custom development and drawing-based manufacturing.

Wire EDM Machine

Overview of Wire EDM

What is Wire EDM?

Wire EDM (WEDM) is an advanced manufacturing process that uses a fine metal wire as an electrode. Under the control of a CNC system, it generates pulsed electrical discharges between the wire and the workpiece to precisely erode the metal material.

This process is especially suitable for machining complex contours, high-hardness materials, and microstructures, and is widely applied in high-end manufacturing fields such as mold making, aerospace, electronics, and medical devices.

How Does Wire EDM Work?

In precision slow wire EDM (WEDM) processing, the workpiece is typically immersed in a working tank filled with deionized water, a type of dielectric fluid. A fine metal wire (such as copper) is clamped by upper and lower wire guides and passes through the submerged machining zone. The CNC system precisely controls the wire’s movement in the X and Y planes according to CAD path instructions. A discharge gap of 0.01–0.05 mm is maintained between the wire electrode and the workpiece. When pulsed current is applied between them, high-frequency electrical discharges occur within the gap, locally melting and eroding the metal. Meanwhile, the deionized water continuously cools the area, removes debris, and maintains electrical insulation—ultimately enabling high-precision cutting or shaping of the workpiece.

Who are our customers?

Our Customer Types

Aerospace, Medical Devices, and Automotive Component Manufacturers

Semiconductor Packaging and Precision Electronic Component Manufacturers

Injection Mold, Stamping Die, and Die-Casting Mold Manufacturers

OEMs and Contract Manufacturers Without In-House WEDM Equipment

Simple Steps to Get an Order at JUNYU

Upload Project Design Files

Send your project designs to us, we will make you perfect plan feedback.

Confirm Our Quote & Production Plan

As long as we received your confirmation, your project will get started.

Receive Your Order at Your Door

Your custom machined parts will be delivered right to your doorstep.