Injection Molding

Injection molding is a processing method that combines injection and mold forming, offering numerous advantages, including:

High production speed, high efficiency, automation capability, a wide variety of colors and materials, the ability to manufacture parts ranging from simple to complex shapes, a broad size range from large to micro parts, high dimensional accuracy, easy mold replacement, and the ability to form complex structures in a single process. Therefore, injection molding is especially suitable for mass production and the manufacturing of complex-shaped products, and it is widely used across various molding and processing industries.

We are a leading provider of professional injection molding services in China. JUNYU is dedicated to delivering high-quality and cost-effective injection molded parts for a wide range of industries, committed to meeting the diverse needs of our clients through superior craftsmanship and service.

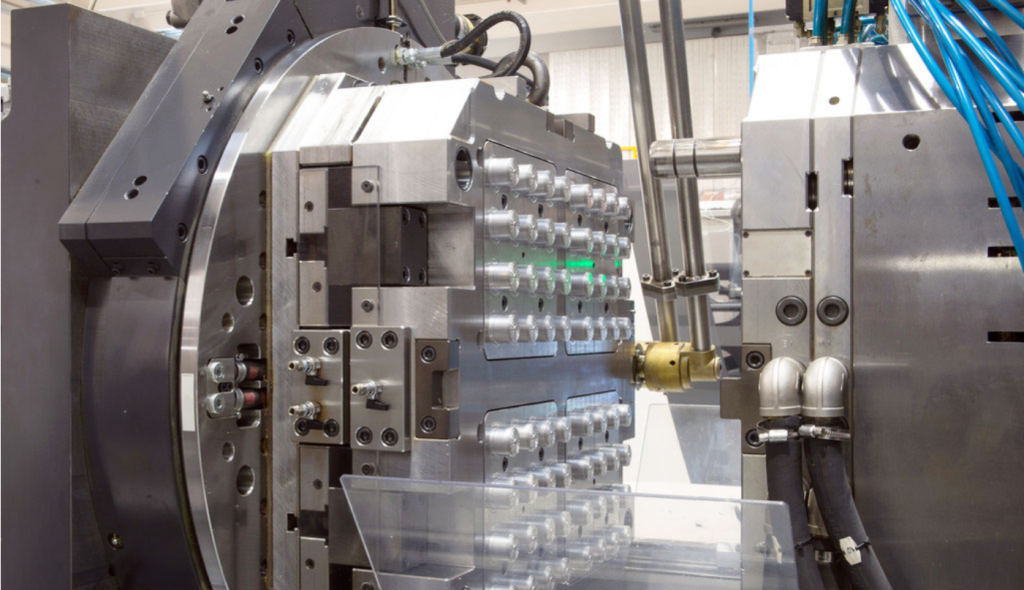

Injection Molding Capabilities

We have advanced injection molding equipment and extensive manufacturing experience, enabling us to meet the diverse needs of various industries for plastic parts. Our main capabilities include:

Clamping Force Range: 30 tons to 1000 tons, meeting the size requirements for various products

Mold Cavities: Single-cavity and multi-cavity molds supported to improve production efficiency

Material Support: Supports thermoplastics such as ABS, PC, PP, PE, PA, POM, TPU, TPE, etc.

Process Types:

Single-color injection molding

Dual-color/multi-color injection molding

Overmolding

Insert molding

Mold Development: In-house mold design and manufacturing capabilities, shortening development cycles

Product Dimensional Tolerance: Precision control according to ISO tolerance standards or customer requirements

Surface Treatment: Can be combined with polishing, texturing, spraying, electroplating, and other post-processing

We are committed to providing our clients with a one-stop solution from product design, mold manufacturing to injection molding.

Why Choose Our Injection Molding Services?

JUNYU is one of the leading mold manufacturers in China. We specialize in providing high-quality product molding solutions for various industries, including medical injection molding, electrical injection molding, automotive injection molding, and more.

To meet the growing demand for plastic products, we continuously upgrade our equipment and technology, dedicated to providing higher-quality injection molding services that ensure we meet all your needs for plastic products and mass production.

What is Injection Molding?

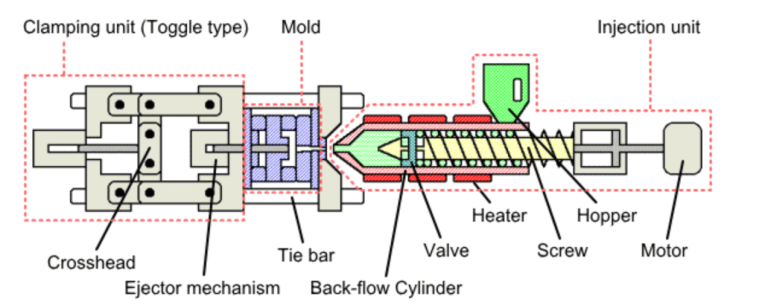

Injection molding is a highly efficient manufacturing process in which molten thermoplastic or thermosetting materials are injected under high pressure into a metal mold, then cooled and solidified to form parts with specific shapes.

The process involves feeding granular or powdered plastic into the injection molding machine’s barrel, where it is melted and plasticized through heating and the shearing action of a rotating screw. The uniform melt is then pushed forward by the screw (or plunger) under high pressure, passing through the nozzle and runner system into the closed mold cavity. The mold is cooled by circulating water, causing the melt to solidify and take shape. Finally, the mold opens and the finished part is ejected.

This process is widely used across various industries, including electronics, automotive, and consumer goods.

Key advantages include: high production efficiency, excellent dimensional accuracy, repeatability, a wide range of material options, high automation capability, low labor cost, minimal material waste, and little to no need for post-processing (such as polishing) after molding.

However, the process also has some disadvantages, such as high upfront mold investment costs and certain limitations in processing geometry or materials.

Why Choose Injection Molding?

The core reason for choosing injection molding lies in its comprehensive advantages in production efficiency, cost control, product performance, and process flexibility, making it widely suitable for the diverse manufacturing needs of various industries. The key benefits include:

1. High-Efficiency Mass Production

Each molding cycle takes only a few seconds to a few minutes. When combined with multi-cavity molds (e.g., 1 mold with 64 cavities) and fully automated production lines, injection molding enables 24/7 continuous operation, with daily output reaching tens of thousands of parts (e.g., bottled water caps).

2. Significant Cost Advantage and Long-Term Cost Efficiency

Although the upfront investment in molds is relatively high, once the mold is completed, the per-part cost during production becomes extremely low. This cost efficiency becomes more significant for production volumes ranging from tens of thousands to millions of units.

3. High Precision and Complex Geometry Support

Injection molding offers excellent dimensional accuracy—typical tolerances are within ±0.1 mm, while precision molding can achieve ±0.01 mm. It supports the production of highly detailed, complex, and thin-walled parts, meeting the stringent requirements of industries like electronics, medical devices, and optics.

4. Broad Material and Structural Adaptability

Injection molding is compatible with almost all thermoplastics (e.g., PP, ABS, PC), and also supports certain thermosetting materials (e.g., phenolic resins) and modified materials (e.g., glass fiber-reinforced or metal-filled compounds). These meet various functional requirements such as high strength and heat resistance.

5. High Material Utilization

Compared to traditional machining, injection molding generates minimal waste. Excess material can typically be recycled and reused, helping reduce overall material loss and cost.

6. Excellent Repeatability

Injection molding is a highly repeatable process, ensuring consistent product quality and performance throughout high-volume production.

7. Easy Automation Integration

Injection molding is well-suited for integration with robotic systems, enabling high-efficiency, fully automated, continuous manufacturing operations.

8. Superior Surface Finish and Appearance

Parts often come out of the mold with excellent surface quality, such as smooth or textured finishes. In most cases, no additional post-processing (e.g., polishing or sanding) is needed, which reduces labor and cost.

Advantages of Injection Molding

High Efficiency for Mass Production

Low Unit Cost at Scale

High Dimensional Accuracy

Excellent Repeatability

Wide Range of Compatible Materials

Design Flexibility

Superior Surface Finish

Material and Scrap Efficiency

Injection Molding Materials

We have the capability to injection mold nearly all types of thermoplastic materials, meeting the needs of a wide range of products.

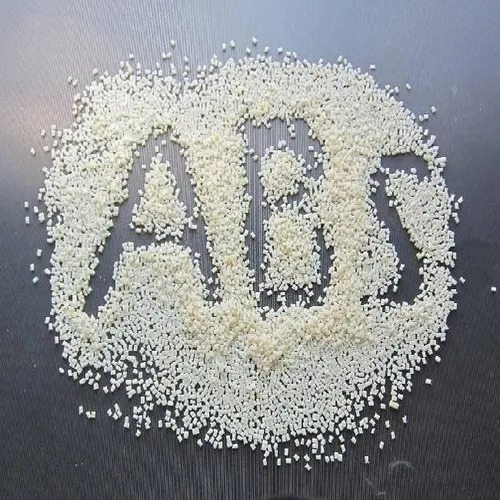

ABS

ABS is one of the most commonly used thermoplastic engineering plastics in injection molding. It is widely applied due to its excellent overall mechanical properties and processability.

Composition and Characteristics of ABS

Synergistic effect of three components:

- Acrylonitrile (A): Provides chemical resistance and hardness

- Butadiene (B): Enhances toughness and impact resistance

- Styrene (S): Ensures surface gloss and processing fluidity

As a result, ABS is a material that combines toughness, hardness, and rigidity. It features easily available raw materials, outstanding comprehensive performance, low cost, and an extremely wide range of applications.

Polycarbonate(PC)

PC (Polycarbonate) is an engineering plastic with excellent overall performance.

It has the following characteristics:

- Perfect Transparency: With a light transmission rate of up to 90%, it is close to glass and is commonly used in optical lenses and beverage bottles (such as space cups).

- Excellent Impact Resistance: Known as “bulletproof plastic,” it can withstand external impacts even when it is only 2mm thick (e.g., automotive lamp covers).

- High Temperature Resistance: The heat distortion temperature is about 120–130°C, and it can withstand steam sterilization, making it suitable for medical instruments.

- Recyclability: PC material is recyclable and meets modern environmental standards.

- UV Resistance: It can be treated to enhance its UV resistance, making it suitable for outdoor environments.

PC plastic can be processed using various methods, including injection molding, extrusion molding, blow molding, and thermoforming.

Nylon

Nylon (chemical name: Polyamide, PA) is a widely used engineering plastic known for its excellent mechanical properties and processing adaptability. It performs exceptionally well in injection molding, extrusion, and machining applications.

Typical Properties:

High Strength + Wear Resistance: Excellent self-lubricating properties, can replace metals in making gears (e.g., sewing machine components).

Chemical Resistance: Resistant to oils and solvents, but tends to absorb moisture (which reduces dimensional stability after absorption).

Processing Temperature: PA66 is around 260–290°C, while PA6 is around 220–250°C.

Typical Applications of Nylon:

| Industry | Application Parts |

| Mechanical Manufacturing | Gears, Bearings, Pulleys, Guides, Seals, Washers, Impellers, Couplings |

| Automotive Industry | Engine Covers, Fuel Tank Caps, Transmission Housing, Interior Clips, Radiator Brackets |

| Electrical & Electronics | Cable Ties, Electrical Enclosures, Plugs and Sockets, Insulating Components |

| Chemical Equipment | Valve Bodies, Pump Housings, Slides, Corrosion-Resistant Connectors, Fluid Transport Components |

| Textile & Light Industry | Spools, Shuttles, Thread Wheels, Loom Guides |

PBT

PBT is a semi-crystalline and commonly used thermoplastic engineering plastic, known for its excellent mechanical properties, chemical stability, heat resistance, and electrical insulation performance. It is mainly used in applications that require high strength, wear resistance, and good dimensional stability, and is widely utilized in the electronics, electrical, and automotive industries.

PBT is suitable for various molding processes, including injection molding, extrusion molding, blow molding, and compression molding.

With its good flowability, PBT meets the requirements of high-precision and high-efficiency production. Typical applications include electrical connectors, power tool housings, and automotive components.

PEI

PEI is a high-performance thermoplastic engineering plastic known for its excellent heat resistance, high strength, dimensional stability, and outstanding electrical insulation properties. It is widely used in demanding industrial applications, particularly in aerospace, electronics, and electrical industries. A well-known commercial brand of PEI is the Ultem® series by SABIC.

Processing Methods:

Injection molding, extrusion molding, compression molding, and 3D printing (FDM-grade available)

Note:

PEI requires high processing temperatures, with a recommended mold temperature of ≥140°C and a melt temperature between 340–400°C. Specialized high-temperature equipment is required for processing.

More material

In addition to commonly used injection molding materials, JUNYU also offers a wider range of options, including POM, PMMA, PEEK, PA, PPS, and more. For detailed material information, please feel free to contact us.

Injection Molding Applications

Injection molding is widely used across various industries due to its high efficiency, precision, and scalability. It enables mass production of complex plastic parts with consistent quality and low cost per unit, making it an essential manufacturing process in both consumer and industrial markets.

AUTOMOTIVE

ELECTRONICS

CONSUMER PRODUCTS

HOUSEHOLD APPLIANCES

PACKAGING

INDUSTRIAL EQUIPMENT

Injection Molding Surface Finishes

Injection molding surface finishes can be customized through mold design and post-processing to meet functional or aesthetic requirements. Below are common types and their applications:

Common Surface Finish Types for Injection-Molded Parts

| Surface Finish Type | Features | Typical Applications |

| High Gloss Polish (Mirror) | Smooth surface with high reflectivity and optical clarity | Phone cases, optical lenses, transparent containers |

| Sandblasting (Matte) | Fine, non-reflective surface with smooth touch and anti-fingerprint | Consumer electronics housings, appliance panels |

| Etching (Chemical Texture) | Mold surface is etched to create leather, fabric, or grain-like textures | Automotive interior parts, remote control housings |

| Plating | Metallic finish or conductive layer for decorative or functional purposes | Cosmetic packaging, automotive buttons, conductive parts |

| Painting | Allows multicolor finishes, special textures, scratch or UV resistance | Home appliances, instrument housings, toys |

| IMD/IML (In-Mold Decoration/Labeling) | Graphic film is molded into part for permanent, wear-resistant designs | Premium phone cases, appliance front panels |

| Laser Etching | Precise marking or engraving without affecting part dimensions | Logos, serial numbers, function button symbols |

Injection Molding FAQs

What is the difference between single-color injection molding and two-color injection molding?

Single-color injection molding and two-color injection molding are two common molding processes, with significant differences in process principles, mold design, material applications, and final product effects.

1. Single-Color Injection Molding

This method uses a single mold and performs one injection cycle with only one material.

Features:

- Relatively simple mold structure

- Uses a standard single-shot injection molding machine

- Suitable for most standard functional components

- Lower cost and high processing efficiency

- Color or pattern variations can be added through post-processing such as painting or printing

2. Two-Color Injection Molding

This process is carried out on the same injection molding machine in two stages. The first material is injected to form part of the product, and then the semi-finished part is placed into another mold cavity to inject the second material, combining two colors or materials in one integrated product.

Features:

- Requires a dedicated two-color injection molding machine and rotary or sliding dual-color mold

- Enables soft-hard material combinations, dual-color effects, and transparent + opaque designs

- Excellent bonding strength and structural stability

- Completed in a single manufacturing cycle, improving efficiency and appearance consistency

- Higher mold and equipment costs, ideal for mid-to-high-end products

How to choose the right injection molding material based on product application?

Selecting the right injection molding material should begin with the product’s intended application, taking into account multiple factors such as performance requirements, budget constraints, processing characteristics, and operating environment.

How to Get An Online Injection Molding Quote?

When you submit an injection molding quote request, we not only provide you with a precise quotation in a short time but also include a professional manufacturing feasibility analysis. Our online quoting platform also offers gate location diagrams, ejector pin layouts, and a pricing curve tool to help you thoroughly evaluate different mold options and choose the optimal manufacturing solution.