What Is an Injection Mold?

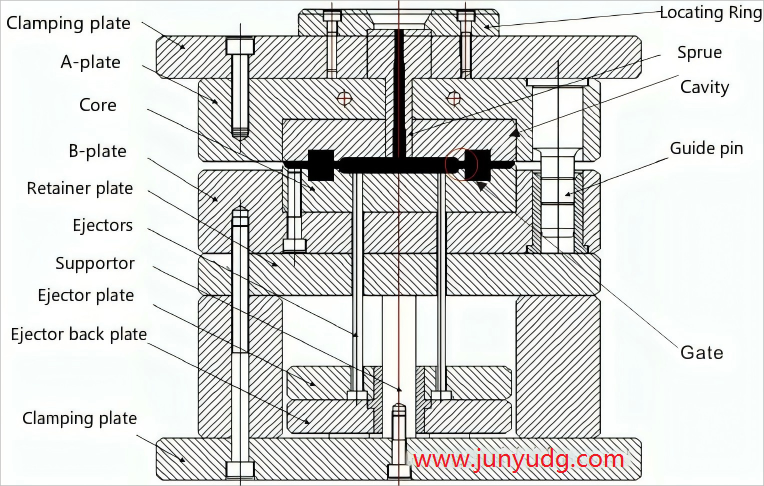

Injection mold is a precision tool used in the injection molding process. Simply put, it functions like a “molding template”: by injecting molten plastic material into the mold cavity and allowing it to cool and solidify, plastic products with shapes exactly matching the cavity can be formed.

The core structure of an injection mold includes a fixed mold (mounted on the injection molding machine) and a moving mold (which moves to close with the fixed mold to form the cavity). It also contains other key components such as the gate (the channel through which plastic is injected), the cooling system (which accelerates plastic solidification), and the venting system (which expels air from the mold cavity).

Injection molds are widely used in industries such as automotive, electronics, medical devices, home appliances, and consumer goods. Products like mobile phone shells, car dashboards, plastic toys, and medical device components are all manufactured using injection molds. The precision and structural design of the mold directly determine the quality, production efficiency, and cost of the final plastic products.

Professional Mold Manufacturing Workshop

Our mold workshop is equipped with a full range of advanced equipment, including high-speed CNC machining centers, precision wire-cutting machines, and mirror EDM machines. These machines are imported from Taiwan, Switzerland, and Japan, ensuring exceptional precision and consistent quality in mold manufacturing.

All production processes are completed in-house, significantly shortening lead times and improving overall project responsiveness.

The workshop is staffed with over 60 highly skilled mold technicians, most of whom have more than 10 years of experience in mold manufacturing. They are well-versed in a wide range of processing techniques and are capable of optimizing cost and efficiency at every stage of the production process.

Comprehensive Mold Manufacturing Technical Support

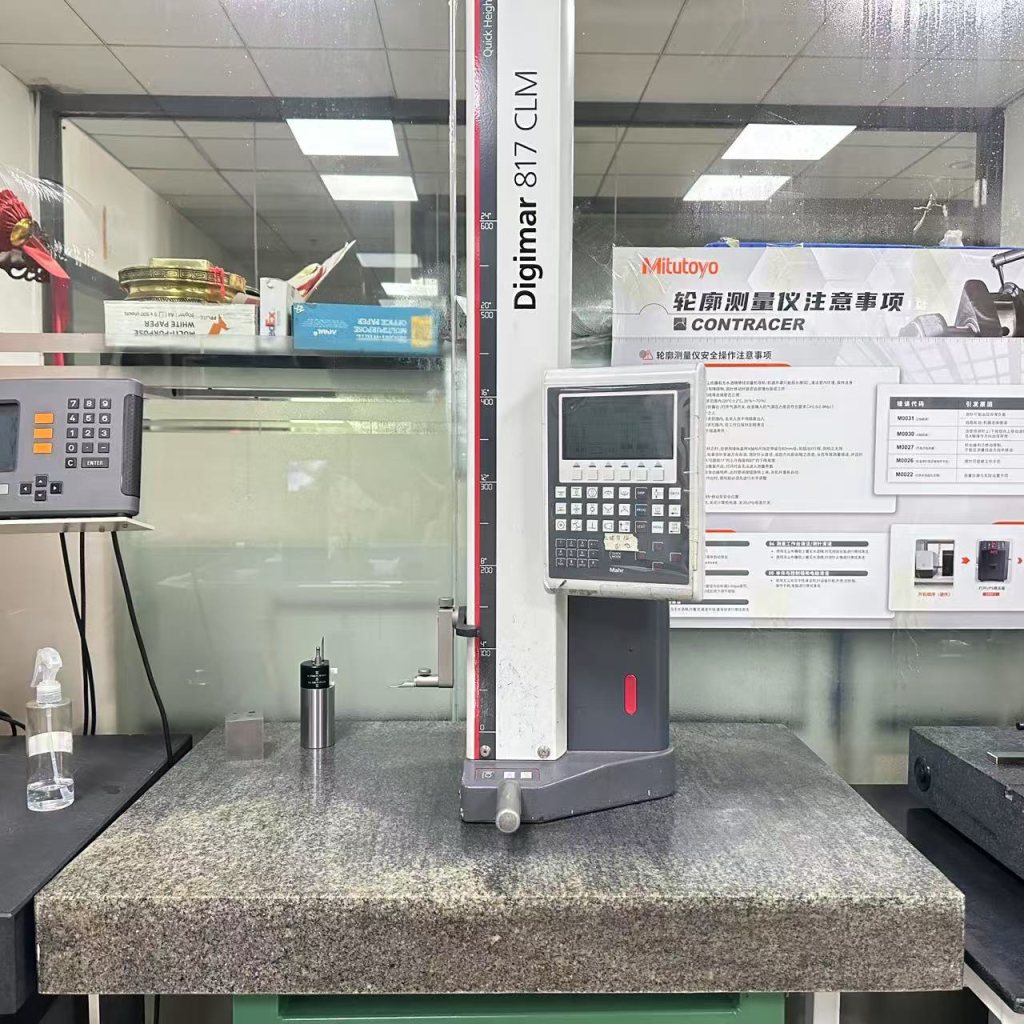

Hexagon 3D Measuring projector

Zeiss 3D Measuring projector

Micro Altimeter

Nikon projector

Nikon tool microscope

Mitutoyo Contour

Laser marking machine

Nikon Altimeter

2D Measuring Projector

As a quality-conscious company, we ensure the accuracy of molds and parts through rigorous dimensional inspections and conduct all necessary additional testing on the molds. We offer comprehensive technical support, perform repairs and rebuilds as needed, and maintain detailed records of all maintenance activities in the mold history. With flexible production methods and a strong focus on customer service, we are able to complete most molds within one to two weeks and provide expedited services for urgent projects. As a professional company, we are committed to listening to our customers’ needs and providing solutions that enhance product quality. For more information on our mold manufacturing capabilities or to request a quote, please contact us directly.

Injection Mold Manufacturing Process

The injection mold manufacturing process is a systematic workflow that spans from initial design to final mold delivery. Each stage is closely interlinked and directly affects the mold’s quality and the efficiency of subsequent mass production. The detailed steps are as follows:

1. Product and Mold Design

Product Analysis: Based on the customer’s drawings (3D models or 2D blueprints), engineers assess product structure, dimensional tolerances, material properties (such as PP, ABS), and intended application environment. They evaluate mold feasibility by identifying issues such as undercuts or uneven wall thickness.

Mold Design: Using CAD software such as UG, AutoCAD, Pro/E, or SolidWorks, the mold is modeled in 3D, focusing on key components:

①avity and Core: Define the final product’s geometry;

②Parting Surface: The interface between the fixed and moving mold, enabling part ejection;

③Gate and Runner System:: Channels for molten plastic to fill the cavity — placement and dimensions are optimized for uniform filling;

④Cooling System: Water channels designed to accelerate cooling and shorten cycle time;

⑤Venting System: Removes trapped air from the cavity to prevent defects like bubbles or short shots;

⑥Ejection Mechanism: Pushes the finished part out of the mold upon opening.

⑦Design Review: Evaluates structural logic, cost-efficiency, and production feasibility. Once optimized, detailed technical drawings are generated for manufacturing.

2. Mold Material Selection and Preparation

Material Selection: Based on part quantity, precision requirements, and plastic type (e.g., glass fiber-reinforced or corrosive resins), suitable mold steels are selected:

For standard plastic parts: S50C, P20 (suitable for low to mid-volume production);

For high-precision or wear-resistant needs: 718H, NAK80 (good polishability), S136 (corrosion-resistant for medical or food-grade parts).

Material Pre-Treatment: Heat treatments such as annealing or quenching are applied to improve machinability and dimensional stability, followed by cutting into rough blanks for processing.

3. Machining of Mold Components

A range of precision machining operations are used to shape the mold components from raw material. Key processes include:

CNC Milling: High-precision 3-axis or 5-axis CNC machines mill complex surfaces and core features, typically achieving ±0.005 mm accuracy.

EDM (Electrical Discharge Machining): Used for deep cavities, narrow slots, or intricate textures that are difficult to mill, delivering high detail fidelity.

Wire Cut EDM: Ideal for inserts, sharp corners, and precise contours — accuracy up to ±0.002 mm.

Grinding: Ensures flatness, perpendicularity, and dimensional accuracy on templates, guide posts, and mating surfaces for accurate mold alignment.

Drilling and Tapping: For cooling channels, screw holes, and auxiliary fittings.

4. Heat Treatment

Critical parts such as the cavity and core are heat treated (e.g., quenching, nitriding) to increase surface hardness (typically HRC50–55) and wear resistance, thereby extending the mold’s service life.

5. Mold Assembly

All machined components — fixed mold, moving mold, guide pillars, ejector system, cooling pipes, etc. — are assembled according to the technical drawings. Fitting tolerances are carefully controlled (e.g., 0.01–0.02 mm for guide components).

Final steps include installing gate bushings, locating rings, and sealing cooling systems, while ensuring venting paths are clear.

6. Mold Trial and Tuning

The assembled mold is mounted on an injection molding machine. Using actual production plastic, a trial injection is performed: molten plastic is injected, cooled, and the part is ejected.

Product Evaluation: Parts are examined for dimensional accuracy, surface finish (checking for sink marks, flash, bubbles), and ease of ejection.

Mold Tuning: Adjustments are made based on issues found — e.g., repositioning gates, optimizing cooling layout, polishing cavity surfaces. Multiple trial runs (T1, T2, etc.) are conducted until quality standards are met.

7. Mold Acceptance and Delivery

After successful trial runs, the mold is cleaned and treated with anti-rust agents. All documentation — drawings, trial reports, etc. — is compiled.

The mold is then packed and prepared for shipping or on-site installation at the production facility.

8. Mass Production Support and Maintenance (Optional)

Support may be provided for production stabilization;

Maintenance guidelines and spare parts replacement schedules are offered;

Technical assistance or mold refurbishment is available in case of wear, leakage, or other failures.

The importance of injection mold manufacturing.

Injection mold manufacturing holds an irreplaceable position in modern manufacturing. Its influence spans across product quality, industrial development, and economic efficiency. The importance of this process is reflected in the following aspects:

1. Determines the Quality and Performance of Plastic Products

- The precision of the mold—such as cavity dimensions and surface finish—directly affects the dimensional tolerances, surface quality (e.g., absence of flash, sink marks), and structural integrity of the plastic parts.

- A well-engineered mold structure—including cooling systems and venting design—ensures uniform melt filling and adequate cooling, preventing common defects like bubbles or warping. This guarantees the final product’s functional performance, including mechanical strength and sealing reliability.

2. Impacts Production Efficiency and Manufacturing Costs

- High-quality molds enable high-speed, stable, continuous production, significantly reducing cycle time (ranging from a few seconds to a few minutes per shot) and improving mass production efficiency.

- The durability of a mold—determined by factors such as heat treatment, hardness, and wear resistance—directly affects its service life. Standard molds can last for tens or hundreds of thousands of cycles, while precision molds can exceed one million cycles. This minimizes downtime due to frequent maintenance or replacements, thereby reducing unit production costs.

3. Supports the Development of Multiple Industries

Injection molds are widely used across numerous sectors including automotive, electronics, medical devices, home appliances, packaging, and consumer goods. Virtually all mass-produced plastic components rely on injection molding. For example:

- In the automotive industry: dashboards, bumpers, air ducts;

- In electronics: mobile phone casings, connectors, enclosures;

- In medical devices: syringes, IV sets, and high-precision consumables.

The level of mold manufacturing directly affects the speed of product innovation and the competitiveness of these industries—particularly in achieving complex geometries and lightweight designs.

4. Reflects the Technological Level of a Manufacturing System

Mold manufacturing integrates a wide range of disciplines, including design (CAD/CAE simulation), precision machining (CNC, EDM, wire cutting), materials engineering, and heat treatment technology. The accuracy and complexity of molds are widely regarded as indicators of a nation’s or enterprise’s manufacturing capabilities.

The development of high-end molds—such as micro-precision molds or multi-cavity molds—is essential for producing high-value-added products and overcoming technical barriers.

5. Drives Product Iteration and Innovation

- The R&D of new plastic products fundamentally depends on mold manufacturing. Efficient mold development workflows—such as rapid prototyping combined with trial optimization—help shorten the time from product design to mass production, accelerating iteration cycles, especially in fast-changing sectors like consumer electronics.

- The flexibility of molds (e.g., replaceable inserts, modular cores) also supports multi-variant production, meeting the demands for customization and personalization in modern markets.

Advantages and Key Characteristics of Injection Mold Manufacturing

As one of the most fundamental processes in modern manufacturing, injection mold manufacturing offers remarkable advantages such as high forming efficiency, consistent product quality, and broad material adaptability. Its processing methods and technical features make it the dominant solution for mass-producing high-precision plastic components. The core advantages and features are outlined below:

Major Advantages

1.High Efficiency for Mass Production

Once the mold is properly tuned, automated continuous production can be achieved using injection molding machines. The cycle time per shot is short (ranging from a few seconds to a few minutes), enabling rapid response to large-scale production demands. The larger the output, the lower the mold cost per unit, resulting in significant economic benefits.

2. Excellent Consistency and High Precision

The dimensional tolerance of mold cavities can reach ±0.005 mm, ensuring that all parts produced from the same mold are highly consistent in size, shape, and physical performance. This eliminates the variations typically found in manual processing and is especially suitable for sectors requiring tight tolerances, such as precision electronics, medical devices, and optical components

3. Capability for High Structural Complexity

Complex mold designs involving multi-cavity layouts, sliders, lifters, and inserts can easily accommodate intricate shapes, internal channels, and multiple side-core pulls.

Integrated design is supported, allowing multiple components to be formed as a single unit, thereby reducing assembly costs and failure rates.

4. Wide Material Compatibility

Injection molds are suitable for a wide range of thermoplastics (e.g., ABS, PP, PC, PA, POM) as well as certain thermosetting plastics and high-performance engineering resins.

Complex geometries and fine structures can be molded, including curved surfaces, undercuts, embedded parts, and threaded features, covering industries such as automotive, home appliances, medical, electronics, and consumer goods.

Mold structures and surface treatments can be customized to match material properties (e.g., wear resistance, corrosion resistance, high-temperature resistance).

High material utilization: Sprues and gates generated during production can be recycled, crushed, and reused, reducing raw material waste and overall production cost.

5. Superior Surface Quality and Aesthetic Capability

Through high-precision machining techniques—such as mirror-finish EDM and fine polishing—molds can produce parts with optical-grade surface finishes that require no secondary surface treatment.

Texturing processes such as chemical etching, leather grain patterns, and laser engraving can be integrated into the mold, enhancing the decorative appeal and tactile quality of the final product.

Key Characteristics

1.High Level of Technical Integration

Injection mold manufacturing involves the integration of multiple advanced technologies, including CAD/CAE design, CNC milling, EDM (Electrical Discharge Machining), and wire-cutting, along with material selection (such as mold steel) and heat treatment processes. It demands high-precision equipment and experienced technical personnel to ensure processing accuracy and reliability.

2.High Upfront Investment & Long Lead Time

Mold design and fabrication incur significant initial costs, especially for complex or multi-cavity molds. The typical lead time ranges from 30 to 90 days, depending on complexity. However, for long-term mass production, the mold cost can be amortized, making it highly economical for products with long life cycles.

3.Strong Dependence on Mold Quality

The rationality of mold structure, machining accuracy, and wear resistance directly affect product outcomes—such as surface finish, dimensional stability, and production efficiency. Poor mold quality leads to frequent breakdowns and maintenance. Hence, strict quality control is essential at every manufacturing stage.

4.Supports Complex, Integrated Forming

Injection molds are capable of forming complex components in a single cycle, including parts with multiple integrated features such as clips, ribs, snap-fits, or embedded structures. This significantly reduces secondary assembly processes, improves efficiency, and ensures product consistency.

These characteristics make injection mold manufacturing an indispensable and irreplaceable process in modern industry—particularly in the mass production of complex plastic components, where it plays a central and strategic role.

Types of Plastic Molding

Injection Molding

Blow Molding

Compression Molding

Extrusion Molding

Rotational Molding

Thermoforming

Plastic Molding Types

Classification of Plastic Molds

Plastic molds are primarily used for shaping thermoplastic materials. Due to variations in application requirements, structural configurations, and molding processes, plastic molds can be categorized in several ways. The most common classifications are as follows:

1. Classification by Molding Process

Injection Molds

The most widely used type. Molten plastic is injected into the mold cavity via an injection molding machine and solidified upon cooling. Common products include plastic toys, household appliance housings, etc.

Extrusion Molds

Used for continuous production of plastic products with a fixed cross-sectional profile, such as plastic pipes, sheets, and profiles.

Blow Molds

Includes extrusion blow molding and stretch blow molding. Mainly used for hollow plastic products such as bottles, containers, and tanks.

Thermoforming Molds

Heated and softened plastic sheets are drawn onto the mold surface using vacuum suction. Commonly used for packaging trays, blister packs, and clamshells.

2. Classification by Mold Structure

Single-Parting Surface Mold (Two-Plate Mold)

Features only one parting line, with the gate located on the parting surface. It has a simple structure and low manufacturing cost, suitable for most plastic products. This is the most basic type of injection mold.

Double-Parting Surface Mold (Three-Plate Mold)

Incorporates a secondary parting surface by adding a runner plate, enabling point gate injection. It allows for better gate positioning (e.g., at the center or edge), producing parts with a cleaner appearance. Ideal for products with central holes or requiring pinpoint gating.

Stack Mold

Designed with multiple layers of cavities (stacked vertically), allowing for higher output within the same mold stroke. Suitable for high-volume production of small parts such as packaging items.

Hot Runner Mold

Equipped with heating elements to keep the runner system molten, eliminating material waste (no sprue or cold runner). Offers short cycle times and high material utilization. However, it has a complex structure and higher cost, ideal for large-scale, high-end production.

3. Classification by Number of Cavities

Single-Cavity Mold

Contains only one cavity, producing one part per cycle. Suitable for large or high-precision parts.

Multi-Cavity Mold

Contains multiple identical cavities within the same mold, enabling simultaneous production of multiple parts per cycle. Enhances productivity and is commonly used for mass production of small plastic parts.

4. Classification by Ejection Mechanism

Standard Ejector Pin Mold

Ejector pins are used to push out the part. This is the most commonly used and simplest ejection method.

Angled Pin Mold (Lifter Mold)

Suitable for parts with side protrusions or undercuts, using inclined lifters to eject the part.

Slider Mold

Utilizes mechanical sliders to achieve side-core pulling and features like thread demolding.

Pneumatic or Hydraulic Core-Pulling Mold

Employed for complex internal structures or deep-hole demolding, commonly found in large industrial parts.

5. Other Common Classification Methods

By Industry Application: Automotive molds, medical molds, electronics molds, packaging molds, optical molds, etc.

By Mold Installation Orientation: Vertical molds, horizontal molds

By Material Flow Direction: Edge-gated molds, center-gated molds, annular-gated molds, etc.

Industries We Serve

Daily necessities field

Electronic and electrical appliances field

Automotive industry field

Medical device field

Packaging field

Toy field

Mold Making FAQ

How long does it take to deliver the mold?

The delivery time depends on the complexity of the mold, typically ranging from 15 days to several months.

How long will the shipping take?

If shipped by sea, the transportation time may exceed one month. If you need the mold urgently, we recommend choosing air transport to shorten delivery time.

Can we sign an NDA before uploading my design?

Of course, we take your design confidentiality very seriously.

What should I pay attention to when designing a mold?

Pay attention to factors such as product structure and functionality compatibility, accuracy and tolerance control, material selection and heat treatment, gating and cooling system design, maintainability and cost control, as well as production efficiency and automation compatibility.