Custom High-Quality Precision Special-Shaped Parts Are Used in Stamping Dies

| Name | Custom high-quality precision special-shaped parts are used in stamping dies. |

| Material | CF-H25S |

| Hardness | 92.2 HRA |

| Specification | Non-standard/Custom |

| Custom | OEM/ODM |

| Surface treatment | None |

| surface finish | Ra0.15-Ra0.3um |

| Wire Diameter | 0.03mm-0.2mm |

| Tolerance | ±0.002mm |

| Mold Type | Stamping mold |

| MOQ | 1PCS |

| Wire Diameter | 0.03mm-0.2mm |

| CNC Machining or Not | CNC Machining |

| Sample | Available |

| Place of Origin | Dongguan GuangDong China |

| Supply Ability | 20000 Pieces Per Month |

| Material Capabilities | 1.2343,1.2083,1.2842,C45(K1045),C2100,C46(K1046),C20,SKD11,SKD61,SKH51,1.2379,k390,ELMAX,SKS3,S45C,S290,HPM31,SLD,YXM1,HAP40,YXR33,HPM38,D2.stavax,S-7,NA20,RD50,RD30,WF30,KG7,WF15,CF-H40S,CF-H25S,SUJ2,etc. |

| Packaging&Delivery Packaging Details | PP bag,carton ,box or according to customer’s requirements |

| Port | GUANGZHOU |

| Lead Time :Quantity(pieces)1-5000 | 3-7days |

| Lead Time :>50000 | TO be negotiated |

| Shipping | Shipped by a convenient and cost-effective way |

Process: on-demand blanking → Rough Grinding→ finish Grinding→ WEDM→ Chamfer and edge treatment→ Cleaning and Packaging

Product parameters

Perpendicularity

0.002MM

Parallelism

0.001MM

Roughness

EDM Roughness: Ra0.4-Ra0.8um

Roughness

Grinding Roughness: Ra0.15-Ra0.2um

Roughness

Wire-Cut Roughness: Ra0.15-Ra0.3um

Why Choose Us

- Over 15 Years of Expertise – Trusted by clients across Japan, Germany, Singapore, Malaysia, and Thailand.

- Direct Factory Advantage – Competitive pricing without unnecessary markups.

- Complimentary Support – Free engineering advice and samples before mass production.

- Guaranteed Precision – Every part is inspected with CMM reports for accuracy.

- On-Time Delivery – Flexible lead times from 7 to 20 days to meet your schedule.

- High Precision– ±0.002mm tolerance

- Lead Time- 7-20 days

- QC Assurance -100% inspection before delivery

Product Overview

This product is a precision wire-cut part exported to Singapore. It features a stable machining tolerance within ±0.002 mm, with geometric tolerances (perpendicularity of 0.002 mm and parallelism of 0.001 mm). The minimum internal radius (R) of this workpiece is R0.1, which is machined using a wire with a diameter of φ0.1 mm.

Customization & Procurement Process

- Requirement Communication – Provide drawings, samples, or specifications

- Quotation – Engineers analyze requirements and provide pricing

- Prototype & Testing – Samples available for trial

- Production – Precision machining with strict QC inspection

- Packaging & Shipping – Customized packaging & global delivery

A brief introduction of Junyu:

Dongguan Junyu Precision Moulds specializes in precision molds and components, and has been upholding ISO9001-certified quality standards since 2008. We manufacture WEDM parts (wire-cut electrical discharge machining parts), which are widely used in connector molds, motor core molds, terminal molds, and automation equipment.

With over 15 years of industry experience and solid technical expertise, we provide reliable quality and customized solutions for global customers in Japan, Germany, Singapore, Malaysia, Thailand, and other regions. We are now seeking to explore more global markets!

Our Exhibition Display Diagram

2015 Japan Exhibition

2018 Japan Exhibition

2019 Japan Exhibition

2019 German Exhibition

2023 Japan Exhibition

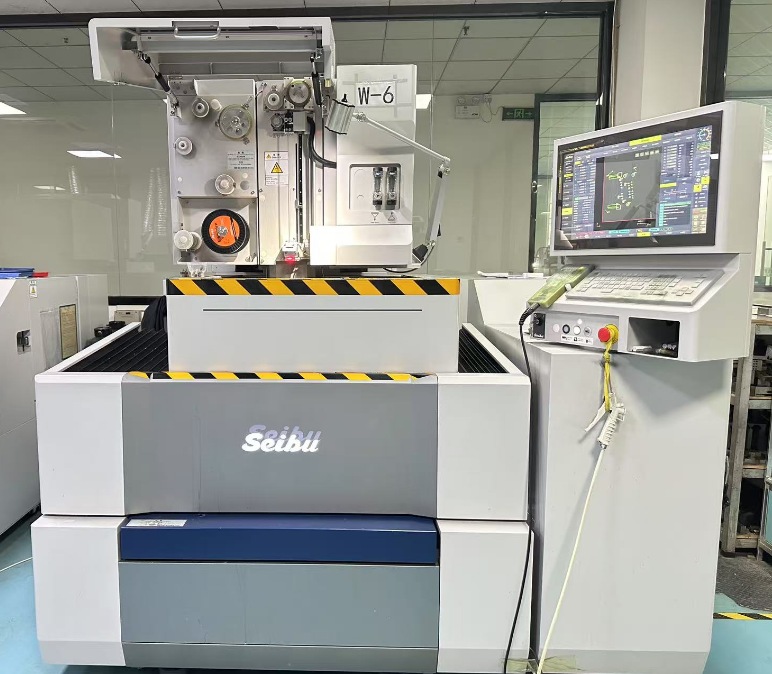

Our WEDM Workshop

Looking for a precision wire-cut parts manufacturer in China?

We provide custom wire EDM solutions with high accuracy and reliable lead times for global B2B buyers.

Contact us today to get a free design review, quotation, and sample for your next project.

Email: info@junyudg.com

WhatsApp: +86 13602364710