How to use G41 and G42 in CNC Turning?

G41 and G42 are crucial tool compensation codes in CNC machining, used for Tool Nose Radius Compensation (TNR). This function adjusts the toolpath based on the shape and size of the tool’s nose radius, ensuring that the actual machined dimensions match the programmed dimensions.

- G41: Tool Nose Radius Compensation – Left

- G42: Tool Nose Radius Compensation – Right

Description

In turning operations, the tool tip is rounded. Without compensation, the machined dimensions—especially on angled or contoured surfaces—may deviate due to the tool nose radius. By using G41 or G42, the CNC system automatically adjusts the cutting path to account for the tool nose geometry, ensuring precise part dimensions.

Table of Contents

- What Are G41 and G42?

- When to Use G41 and G42 in Turning

- How to Use G41 and G42 in CNC Turning

· Step 1: Define the Tool Nose Radius

· Step 2: Choose the Compensation Direction

· Step 3: Insert G41/G42 into the Program

· Step 4: Cancel Compensation with G40 - Common Mistakes to Avoid

- Conclusion

- Our CNC Machining Capabilities

- Application Industry

What Are G41 and G42 ?

G41 (Left Compensation): Offsets the tool to the left of the programmed path, relative to the direction of tool movement.

G42 (Right Compensation): Offsets the tool to the right of the programmed path, relative to the direction of tool movement.

These codes are essential for accurately machining angled or contoured surfaces, as they help ensure the actual cut matches the intended dimensions, even when using a tool with a rounded tip.

When to Use G41 and G42 in Turning

In CNC turning, G41 and G42 are typically used when:

Apply G41/G42 just before the final contouring cut.

Always include a lead-in move before the compensated path and a lead-out before cancelling with G40.

Make sure the tool nose radius and orientation are correctly set in the tool offset table.

| Tool Movement Direction | Insert Position (Facing Toolpath) | Use Code |

| Right ➡ Left | Left side of path | G41 |

| Left ➡ Right | Right side of path | G42 |

How to use G41 and G42 in CNC Turning

Here’s a step-by-step breakdown of how to apply G41/G42 in your CNC turning program:

Step 1: Define the Tool Nose Radius

Before using G41 or G42, input the nose radius of the tool into the tool offset table on your CNC machine.

Example:Tool 1 → Nose Radius = 0.4 mm

Step 2: Choose the Correct Compensation Code

| Turning Type | Tool Movement Direction | Insert Position | Use Code |

| External Turning | Right ➡ Left | Right side | G42 |

| Internal Turning | Right ➡ Left | Left side | G41 |

Tip: Determine the side of the insert based on the direction of tool travel and where the insert lies relative to the path.

Step 3: Apply G41 or G42 in the Program

Insert G41 or G42 before the finishing contouring pass.

Must be activated on a linear interpolation move (G01), not rapid move (G00).

Step 4: Cancel Compensation with G40

Use G40 to turn off G41/G42 after the compensated moves.

Apply it on a linear move (G01) for safety.

Common Mistakes to Avoid

- Forgetting to enter the tool nose radius in the offset table

- Activating G41/G42 with G00 instead of G01

- Not canceling with G40 after contouring

- Using the wrong code (G41 vs G42) for the turning direction

Conclusion

If you’re using the SC-CNC series training lathes, you’re in luck — these machines fully support G41/G42 compensation logic and come with preconfigured tool compensation parameters in their CNC controllers, making them ideal for beginner to intermediate level training and education.

In CNC turning, mastering the use of G41 and G42 is essential for achieving high machining accuracy, maintaining consistency, and adapting to different tool geometries. Whether you’re working on prototyping or mass production, understanding and correctly applying cutter compensation is a fundamental skill every CNC programmer should possess.

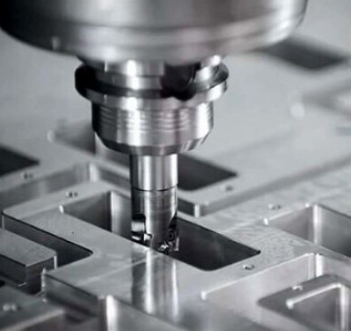

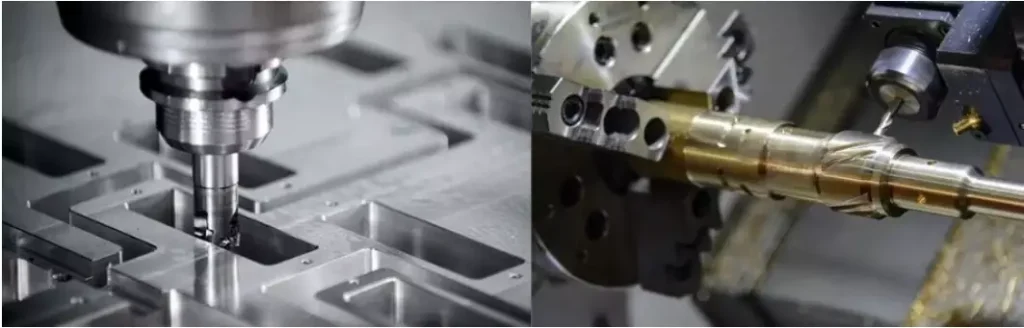

Our CNC Machining Capabilities

Application Industry

Aerospace

Automobile manufacturing

Electronics

Medical

Mold processing

Precision instruments

Energy

Rail transportation