Other Surface Finishing

Mass finishing processes have been widely adopted across the manufacturing industry and are recognized as an efficient method for achieving controlled chamfers and quality surface finishes on a variety of machined and sheet metal parts. As industrial technology continues to advance, many new surface treatment processes are emerging. We have the capability to offer a range of surface treatments tailored to the specific characteristics of our customers’ parts. Below are some of the surface treatment technologies we provide.

Polishing

Features: The polishing process is designed to improve the surface finish of a workpiece, making it smoother and finer, and is often used to achieve a mirror-like effect. It can be performed manually using wool wheels and polishing sponges with abrasive paste, or mechanically through methods such as vibratory polishing and tumbling. Depending on customer requirements, different levels of gloss can be achieved to balance both functional and aesthetic needs, meeting a wide range of surface finish specifications.

Application:

The polishing process is widely used in the following fields:

- Aerospace: Applied to the finishing of precision structural components, refining surface appearance and mating surfaces to improve assembly accuracy and aerodynamic performance.

- Metal Processing Industry: Applied to the surface treatment of mechanical components such as gears, shafts, and valve bodies, enhancing surface finish and dimensional fitting accuracy.

- Mold Manufacturing: Used for polishing injection molds, stamping dies, and other tooling to improve demolding performance and surface quality.

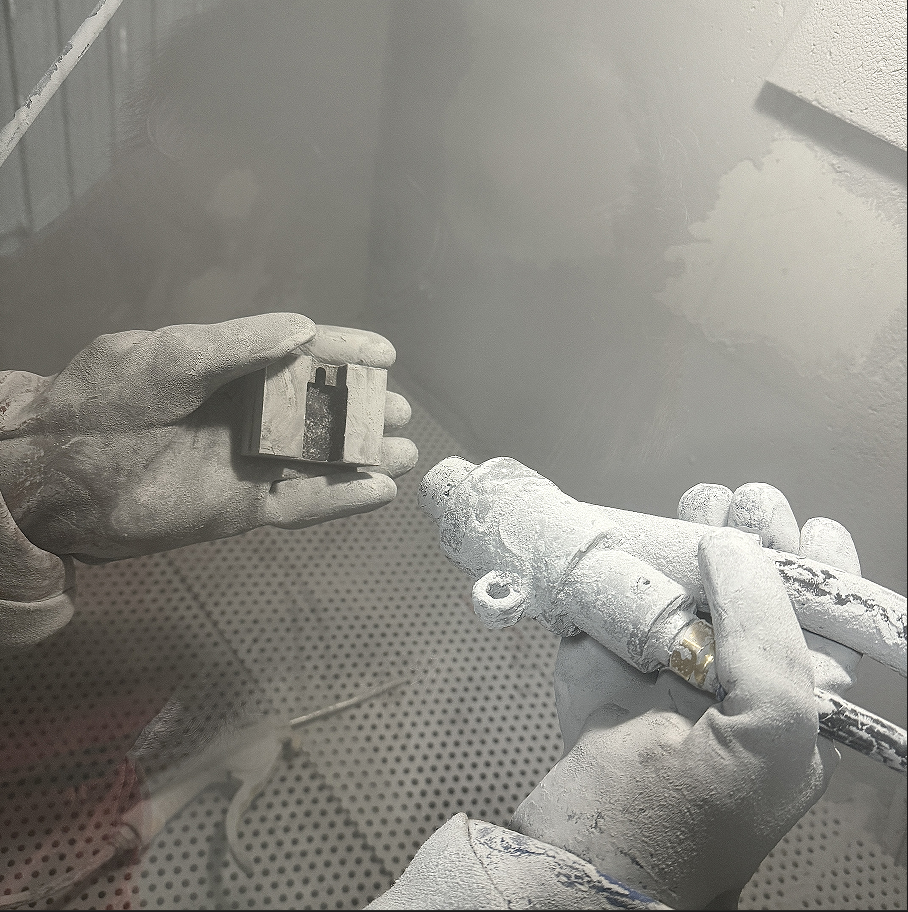

Sandblasting

Features: Sandblasting can effectively remove surface contaminants such as scale, rust, old coatings, and oil from workpieces, providing excellent cleaning results. It also increases surface roughness and enhances the fatigue resistance of metal materials, thereby extending the service life of the components. Additionally, the uniform roughening achieved through sandblasting improves coating adhesion and durability, reducing issues such as blistering and peeling.

Application:

- Metal surface treatment: Used to remove scale, rust, oil stains, and other contaminants from the surface of workpieces, improving cleanliness and enhancing the adhesion of subsequent processes.

- Casting and forging industry: Effectively removes residual sand cores, oxide layers, and burrs from the surfaces of cast and forged parts, improving dimensional accuracy and surface quality.

- Machined parts treatment: Eliminates burrs and machining residues generated during processing, optimizes surface condition, and extends the service life of components.

- Surface homogenization and cleaning of components: Provides a uniform and stable base surface for subsequent processes such as painting, electroplating, and bonding.

- Aesthetic improvement: Sandblasting can create matte, satin, or uniformly textured surfaces, enhancing the visual appearance and overall surface consistency of products.

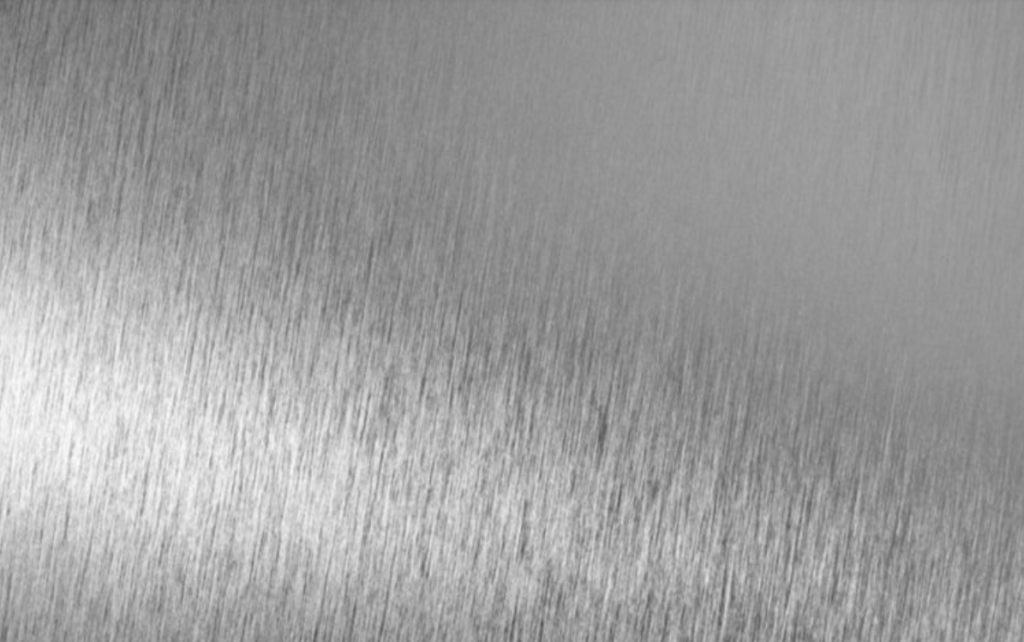

Wire Drawing

Features: Wire drawing treatment can partially conceal scratches and minor surface defects, giving the metal a non-mirror-like, matte metallic texture. It produces a silky, satin-like finish with a strong decorative effect.

Application:Home appliance housings (such as refrigerators, stainless steel stoves)3C products (mobile phone cases, laptopshells)Architectural decoration (elevator panels, stainless steel doors)Mechanical parts, metal sheets, and decorative tool components

Passivation

Features: Removes surface contaminants, enhances corrosion resistance, reduces the risk of product contamination, extends equipment and system maintenance intervals, and improves overall durability.

Application: Stainless steel medical instruments, food processing equipment, chemical equipment and pressure vessels, semiconductor and electronic components, high-precision aerospace parts.

To make sure which method is the best for your parts, contact us and our engineers will sort out the best solution for you