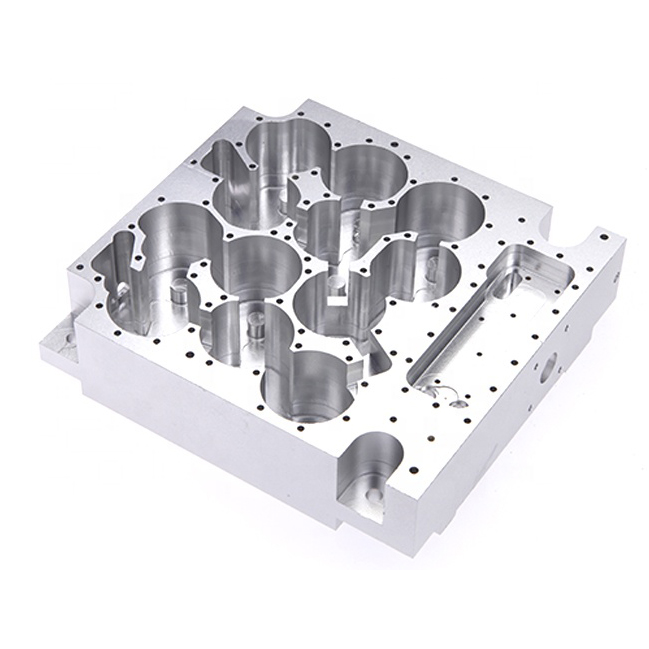

Precision CNC Machining Aluminum Al6061 Parts

- Material: Al6061

- Treatment: Sandblasted Anodized

- Machining process:raw material →CNC milling→ WEDM→edge burr treatment →sandblasting and anodized

- Equipment used–CNC machine、WEDM machine

- Testing tools and equipment – Three-coordinate, Height gauge, profile projector

- Packing –5-layer corrugated paper outer box + bubble bag + pearl sponge

- Application fields: Automotive, Automation, Test systems, Sensors, Medical, Sports, Consumer, Home appliance, Electronic, Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery, Optical, Lighting, Security and safety, AOI, SMT equipment, etc

Description

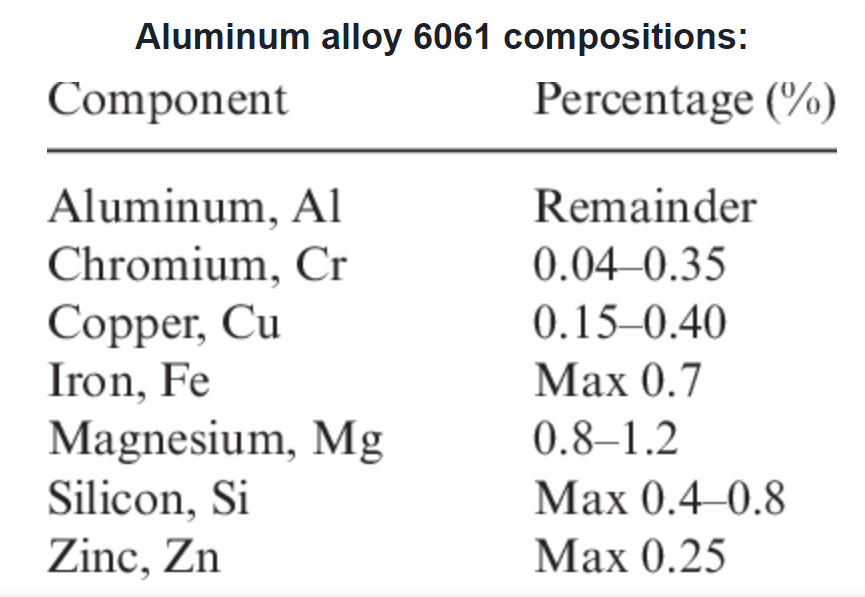

CNC Machining material –Al6061-T6 aluminum alloy rod.

A6061-T6 is an aluminum, magnesium, and silicon alloy that is heat-treated and has excellent corrosion resistance. Its strength and corrosion resistance are significantly improved, and it has good uniformity. 6061 T6 features high strength, high hardness (up to HV90), good machinability, and excellent anodizing properties. The surface is free of pitting and pores, with good flatness. This material enhances processing efficiency and reduces material costs.

6061 Features:Tensile strength: 105-290 MPa, Yield strength: 85-240 MPa, Elongation: 8-16%.

Structure and Properties of the Oxide Film on Anodized Aluminum Plate:

The anodic oxide film consists of two layers: the outer layer is a porous thick layer, which grows on a dense inner layer with dielectric properties, known as the barrier layer (also called the active layer).

Observation under an electron microscope shows that nearly all the longitudinal and transverse planes of the film layer are tubular pores that are perpendicular to the metal surface. These pores penetrate the outer layer of the oxide film and extend to the barrier layer at the interface between the oxide film and the metal. Each pore serves as the main axis, and dense alumina forms a honeycomb hexagonal unit, known as a unit cell. The entire film layer consists of countless such unit cells.

The barrier layer is made of anhydrous alumina, which is thin, dense, has high hardness, and effectively prevents current from passing through. The thickness of the barrier layer is about 0.05 μm, accounting for 0.5%-2.0% of the total film thickness. The porous outer layer of the oxide film mainly consists of amorphous alumina and a small amount of hydrated alumina, and also contains cations from the electrolyte.

When the electrolyte is sulfuric acid, the sulfate content in the membrane layer is typically 13%-17%. The excellent properties of the oxide film are mainly determined by the thickness and porosity of the porous outer layer, which is closely related to the anodizing process conditions.