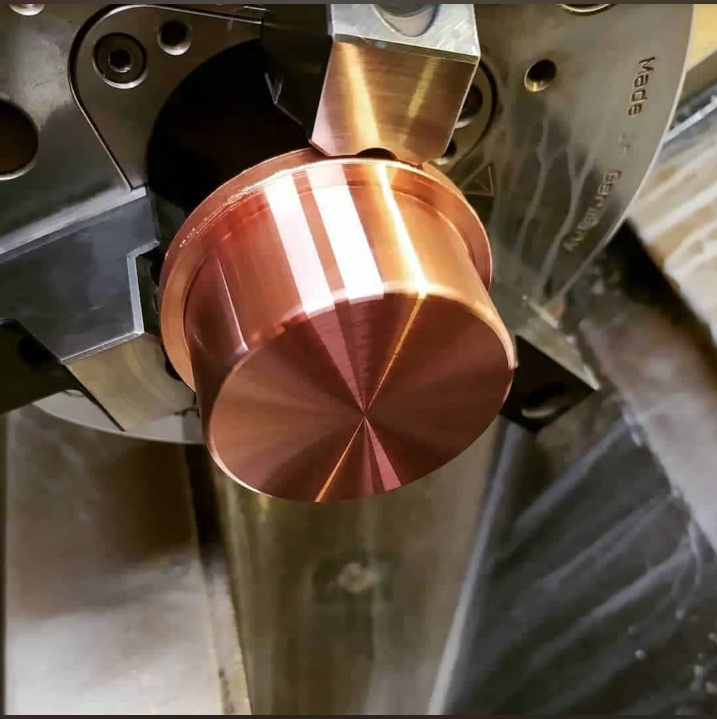

CNC Turning Brass and Cooper Parts

Brass is a specialized copper alloy primarily composed of copper and zinc, and is well known for its distinctive yellow appearance. The copper content in brass typically ranges from 56% to 90%, with a melting point between 900°C and 940°C. It possesses excellent mechanical properties and good wear resistance, making it a critical material in component manufacturing. Due to its superior material characteristics, brass is widely used in the production of precision parts such as automotive components, medical devices, and electronic fittings. Compared with other metal CNC turning processes, brass CNC machining offers several advantages, which contributes to its high demand in the field of precision engineering.

Materials– CNC Turning Brass and Copper

CNC Turning for Brass Materials Parts

360 brass is known as machinable brass, and is also commonly referred to as free-cutting brass or easy-to-machine brass. The machinability of 360 brass is the highest among all copper alloys. It offers excellent cutting performance, reducing tool wear during machining, and is suitable for various machining operations such as turning, milling, drilling, and tapping. It can be precisely machined into parts of various shapes and sizes to meet the needs of different applications. 360 brass is used to manufacture various components such as gears, locks, pipes, and trim parts. Additionally, 360 brass is widely used in electronic hardware and contacts, musical instruments, automatic screw machine parts, bolts, faucet seats, fluid connectors, and other fields.

| Brass | ||||

| Yield Strength (tensile) | Elongation at Break | Hardness | Density | Maximum Temp |

| 15,000 psi | 53% | Rockwell B35 | 0.307 Ibs / cu. in. | 1650°F |

CNC Turning for Bronze Materials Parts

932 bronze is a high-performance copper alloy, also known as CDA932 or C93200 bearing bronze. It has high strength and hardness, allowing it to withstand significant mechanical loads. Due to its content of tin, lead, and zinc, it offers excellent wear and corrosion resistance. It is most commonly used in bearings, bushings, and thrust washers.

| Bronze | ||||

| Yield Strength (tensile) | Elongation at Break | Hardness | Density | Maximum Temp |

| 18,000 psi | 10% | Rockwell B34 | 0.322 Ibs / cu. in. | 500°F |

CNC Turning for Copper Material Parts

The excellent thermal and electrical conductivity of 101 and 110 copper alloys makes them a natural choice for bus bars, wire connectors, and other electrical applications. 101 copper (also known as superconducting copper) is more conductive due to its high purity (99.99% copper) but is more cost-effective because 110 is easier to process.

110 Copper

The full name of 110 copper is C11000, which belongs to the category of electrolytic tough copper (ECP). It has good electrical conductivity, thermal conductivity, corrosion resistance, and excellent machinability.

C11000 copper contains approximately 99.9% copper and is low in oxygen content. Due to the low oxygen content, it exhibits excellent electrical conductivity, superior ductility and toughness, good corrosion resistance, and excellent weldability.

| Tensile Strength, Yield (MPa) | Coefficient of Thermal Expansion: | Density (p) | Melting Point | Elongation (ε) at break |

| 32,000 psi | 0.0000098°F (68-572°F) | 0.321-.323 lbs/cu in | 1949°F | 55% (in 2″) |

C10100 Copper

C10100 copper is oxygen-free copper with a purity of over 99.99%, containing extremely low levels of impurities. It has excellent electrical and thermal conductivity, good machinability, and corrosion resistance. It can be applied in high-end manufacturing industries: in the production of precision instruments, meters, sensors, and other devices, it serves as a key material for conductive and thermal components, helping to improve the accuracy and stability of equipment.

| Tensile Strength,Yield (MPa) | Hardness VPN | Density(p) | Melting Point | Elongation (ε) at break |

| 200-400 MPa | 40-120 | 8.92 g/cm3 | 1083°C | 5-50% |

The Leading Precision Brass CNC Turning Supplier – JUNYU

JUNYU is a leading CNC brass turning supplier in China, specializing in the precision manufacturing of brass components in small, medium, large, and jumbo batch sizes. Our CNC turning center is equipped with advanced numerical control equipment and operated by a team of experienced engineers, enabling us to meet the diverse machining needs of our clients. We are confident in our ability to be your reliable long-term business partner.

With the support of our multi-functional machining centers, we offer both turning and milling services for a wide range of brass components, including those with complex geometries and strict dimensional requirements. To ensure the safety, quality, and reliability of every product, we enforce rigorous design reviews and strict quality control throughout the production process, striving for excellence in every detail.

Leveraging our well-established global logistics network, you can easily place orders for custom brass turned parts, which we will deliver efficiently to destinations worldwide via express shipping.

Properties of Brass

Low Friction Coefficient

Brass has a naturally low coefficient of friction, making it an ideal material for CNC-manufactured automotive components that require smooth motion and minimal wear.

Excellent Corrosion Resistance

Corrosion can significantly reduce the lifespan of automotive parts. Thanks to its inherent corrosion resistance, brass remains rust-free and ensures long-term reliability in harsh environments.

High Heat Resistance

Brass exhibits excellent thermal stability, allowing CNC brass parts to maintain their performance and structural integrity even under high-temperature operating conditions.

High Durability

Brass is a robust and long-lasting material. CNC-machined brass components are known for their durability and extended service life.

Superior Machinability

Brass is highly machinable due to its excellent malleability and ductility. It can be precision-machined into components of various shapes, sizes, and surface finishes, making it ideal for complex or custom designs.