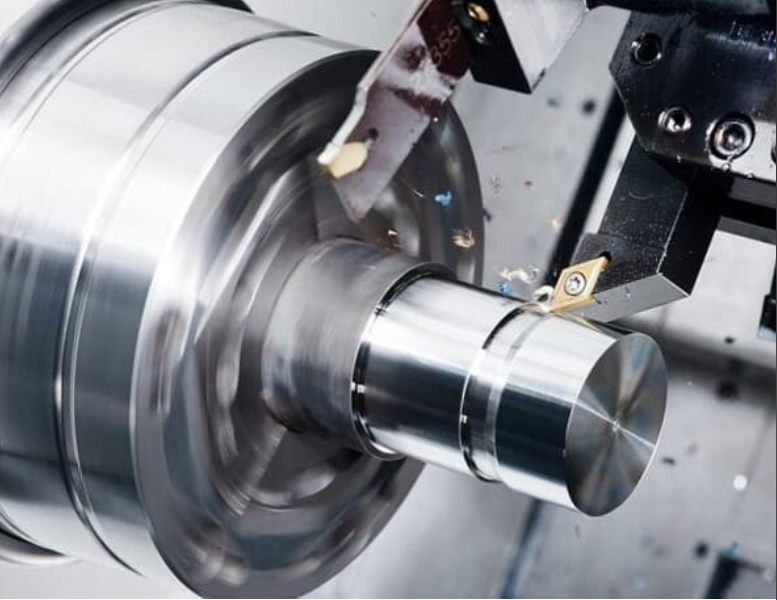

CNC Turning Titanium Parts

Titanium is a metal with unique properties. Due to its low density, high strength, resistance to both high and low temperatures, and excellent corrosion resistance, it is widely used in the aerospace industry. In addition to aerospace applications, titanium is also extensively utilized in general industries, construction, two- and four-wheeled vehicles, and even consumer products.

Titanium alloys are notoriously difficult to machine, especially in high-temperature environments (above 600°C), where they tend to react with elements such as oxygen, nitrogen, and hydrogen. These reactions can degrade the material’s properties and increase the difficulty of subsequent machining processes. Despite these challenges, titanium continues to play an indispensable role in numerous high-performance engineering fields.

About the CNC Turning Material—Titanium

Titanium ores mainly consist of ilmenite and rutile. The two key advantages of titanium are its high specific strength and excellent corrosion resistance, which make it highly applicable in fields such as aerospace, defense, energy, chemical industry, metallurgy, construction, and transportation. The abundant titanium ore reserves provide a resource base for the wide application of titanium materials.

| Yield Strength | Elongation at Break | Hardness | Density | Max Temp |

| 120,000 PSI | 10% | Rockwell C30 | 0.16 Ibs / cu. in | 3000°F |

China’s top Class Titanium CNC Turning Manufacturer

Manufacturing high-quality turned titanium parts is a challenging task for most CNC machining companies. However, several top-tier manufacturers in China have demonstrated exceptional capabilities in this field—JUNYU stands out as one of the leading experts in titanium CNC turning.

JUNYU operates over 70 advanced CNC machining units, including milling machines, lathes, drilling machines, precision wire-cut EDM, precision discharge machines, and optical profile grinders. With more than a decade of experience in precision manufacturing, our engineering team is highly skilled in delivering customized machining solutions and professional design support based on client needs.

We are committed to providing consistently high-quality CNC turning services at competitive prices. Through advanced craftsmanship, efficient production capacity, and responsive technical support, we strive to fully meet our customers’ dual demands for quality and efficiency.

The Characteristics of Machining Center Processing Titanium Alloy

The machining center can process multiple parts simultaneously, significantly improving production efficiency. It enhances machining accuracy and ensures product consistency. With the numerical control tool compensation function, the machining center fully utilizes the inherent precision of the equipment. It offers high adaptability and machining flexibility, making it suitable for a wide range of production tasks. The machining center integrates multiple functions into a single system, capable of completing milling, drilling, boring, tapping, and other operations in one setup. It allows for precise cost estimation and effective control of the production schedule. No special fixtures are required, helping reduce tooling costs and shorten the production cycle. It greatly reduces the labor intensity of operators, improving workplace safety and ergonomic conditions. Multi-axis machining can be carried out using CAD/CAM software such as UG (Unigraphics), facilitating seamless integration between design and manufacturing.