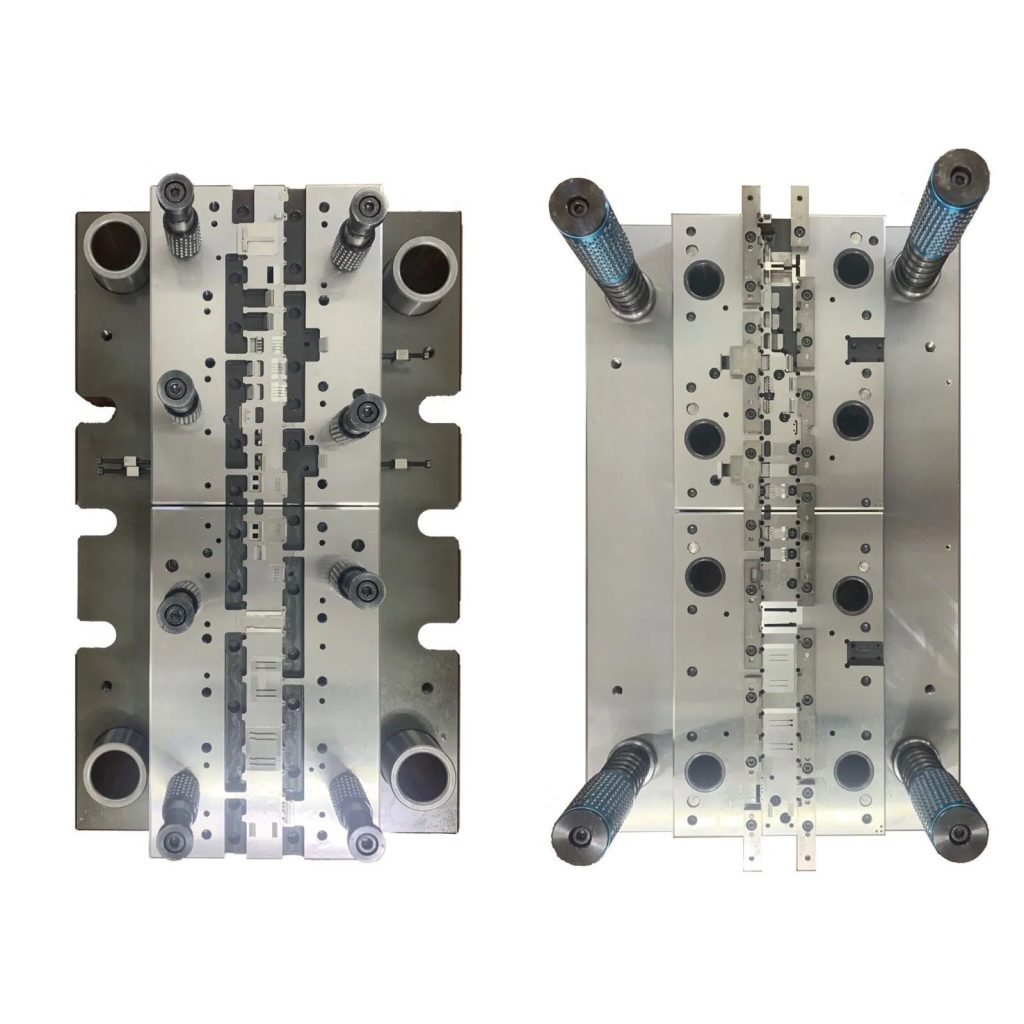

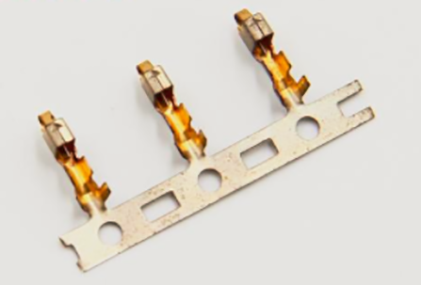

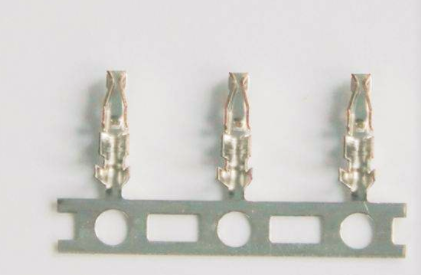

This mold uses Misumi guide pillars and bushings. It contains many precision lower mold inserts, which are processed by wire electrical discharge machining (WEDM), with a tolerance of±0.002mm and a surface finish of Ra0.1μm. There are also numerous precision tungsten steel punches manufactured using optical projection grinding, achieving a tolerance of±0.002mm and a surface finish of Ra0.15μm. Additionally, some components are processed using CNC machining, surface grinding, and precision electrical discharge machining (EDM). The mold is sold to Japan.

Stamping Product Display

Junyu Mould’s advantage :

- Reply to your inquiry within 24 hours.

- Reply to your questions within 24 hours (or faster) during mold making.

- Our salespeople have design experience and can communicate smoothly on technical issues.

- Most of the engineers have more than ten years of work experience.

Junyu Mould Team

Junyu Mould is a professional mold manufacturing enterprise, deeply engaged in the field of mold development and injection molding services. We have more than 15 years of experience in OEM manufacturing, private brand operation and global sourcing, providing support to all customers. The company has its own factory covering an area of 3,000 square meters, and conducts business relying on China’s “cost-effective” manufacturing advantages.

Our Services

Junyu Mould is committed to providing precision high-speed metal stamping dies, plastic moulds, and precision mould component processing. It has integrated service capabilities covering mould design, mould manufacturing, mould optimization, component production, and assembly. The company’s customers mainly come from industries such as automotive, electronic & electrical, medical, daily necessities, new energy, hardware products, and packaging.

Our Goal

We uphold the service tenet of “Responsibility, Innovation, Gratitude, Dedication, Sharing, and Win-Win”, and are committed to meeting your needs. Choose Junyu Mould’s services, and we ensure you are fully satisfied.atitude, Dedication, Sharing, and Win-Win”, and are committed to meeting your needs. Choose Junyu Mould’s services, and we ensure you are fully satisfied.

Professional Mold Manufacturing Workshop

Our Mold Workshop

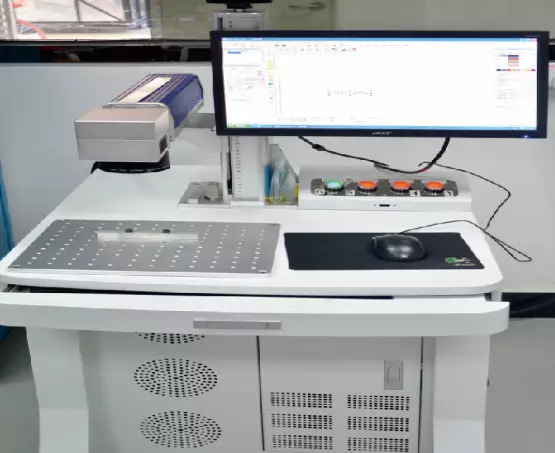

Our mold workshop is equipped with a full set of advanced equipment, including precision high-speed CNC machining centers, precision wire-cutting machines, mirror EDM machines, and optical projection grinding machines. All these devices are imported from Japan, ensuring extremely high precision and consistent quality in mold manufacturing.

The workshop has more than 60 highly skilled mold technicians, most of whom have over 10 years of experience in mold manufacturing. They are proficient in various processing techniques and can optimize cost and efficiency at every stage of the production process.

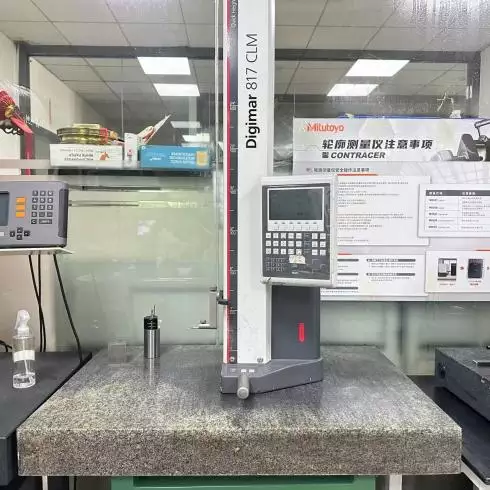

Comprehensive Mold Manufacturing Technical Support

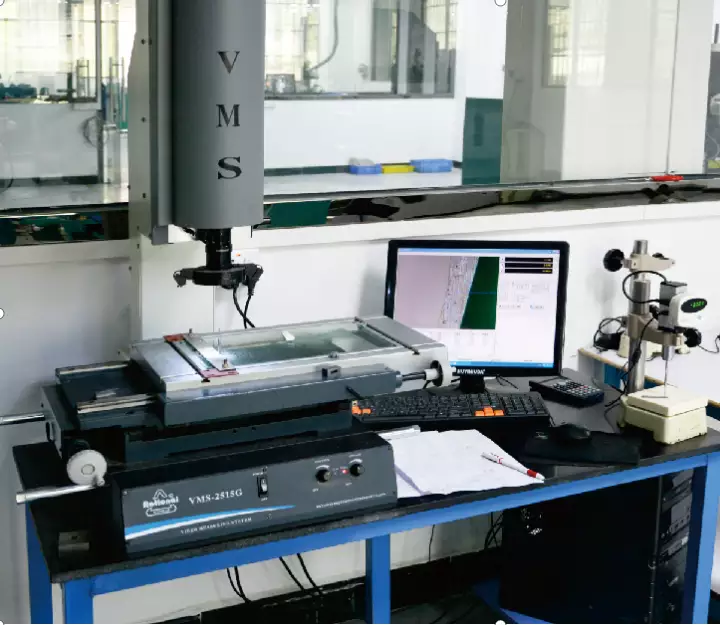

As a quality-focused enterprise, we are equipped with multiple high-precision measuring instruments imported from Japan and Switzerland. All molds and components undergo rigorous dimensional inspection to ensure precision meets standards; meanwhile, we conduct all necessary additional tests on molds to achieve comprehensive quality control.

In terms of services, we provide full-range technical support, and can offer mold repair and renovation services according to customer needs. We also record every maintenance activity in detail in the dedicated mold files, enabling full-lifecycle traceable management.

For more information about our mold manufacturing capabilities or to request a quote, please feel free to contact us directly.

Contact Us

Email: info@junyudg.com

WhatsApp: +86 13602364710

Hot Tags: Precision Injection Mold Machining ,high speed stamping mold making , CNC Machining ,CNC Turning,CNC Milling Steel Blocks,precision, CNC Turning Aluminium , Mold insert Machining,precision EDM parts machining ,precision WEDM parts Machining,Optical Projection Grinding (OPG) Part Machining.