High-Precision Rapid Prototyping & Machining Services

We offer a comprehensive range of CNC machining and rapid prototyping OEM/ODM services, specializing in the production of parts with varying levels of complexity—from simple structures to intricate geometries with tight tolerance requirements. Based on specific customer needs, we utilize processes such as EDM, precision wire cutting, and high-accuracy grinding to ensure dimensional accuracy and part quality. To meet the demands of various industries, we also provide a wide selection of value-added services to help your project move forward efficiently and successfully.

CNC Machining Service

CNC (Computer Numerical Control) is a manufacturing process that uses pre-programmed instructions (such as G-code) to automatically control machine tools—including lathes, mills, drills, and more—via a computer system to perform various machining operations.

With advanced CNC machining equipment, we are fully capable of providing customers with efficient, precise, and reliable one-stop CNC machining services, covering the entire spectrum from rapid prototyping to large-scale production.

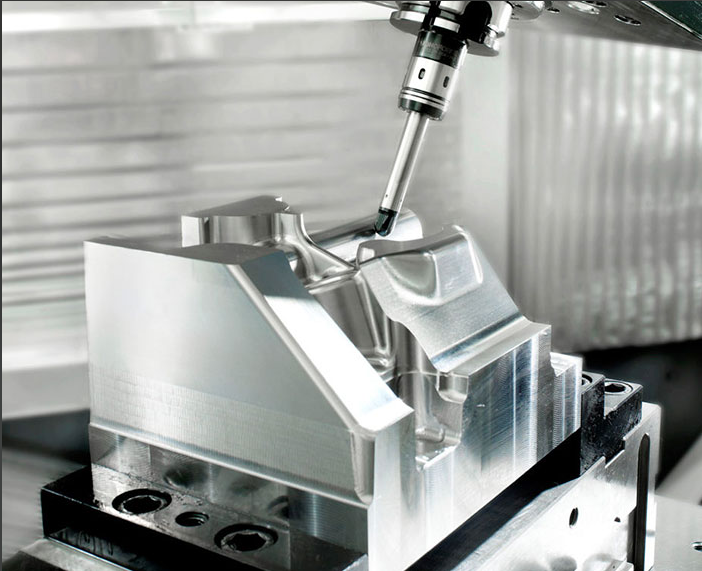

CNC Milling Service

CNC milling is one of the most widely used processes in computer numerical control (CNC) machining. It utilizes multi-axis rotating cutting tools to efficiently remove material from a workpiece, enabling the high-precision manufacturing of complex parts.

We offer customized CNC milling services for both metal and plastic materials. Whether your parts are simple or complex in geometry, we can machine them with precision to meet a wide range of needs—from rapid prototyping to full-scale production.

CNC Turning Service

CNC Turning is a commonly used computer numerical control (CNC) machining method. It involves the use of a CNC lathe, where pre-programmed instructions control the movement of cutting tools along defined paths. The workpiece, typically in the form of a bar or block, rotates at high speed while the tool performs precise cutting operations such as outer diameter turning, internal boring, facing, threading, and grooving. This process is especially suitable for machining rotationally symmetrical parts such as shafts, sleeves, and threaded components.

Wire EDM Service

JUNYU utilizes advanced precision wire EDM equipment to machine high-precision metal parts based on your CAD drawings. Using a fine metal wire (such as copper or molybdenum) as the electrode, material is gradually eroded through pulsed electrical discharges between the electrode and the workpiece, enabling the cutting of complex contours and intricate structures.

Optical Profile Grinding Service

Optical projection grinding is a high-precision grinding technique that uses an optical projection system to enlarge and project the contour of a workpiece onto a screen. The operator precisely grinds the workpiece by observing the projected image. This method is mainly used for micrometer-level shaping of complex curves and profiles.

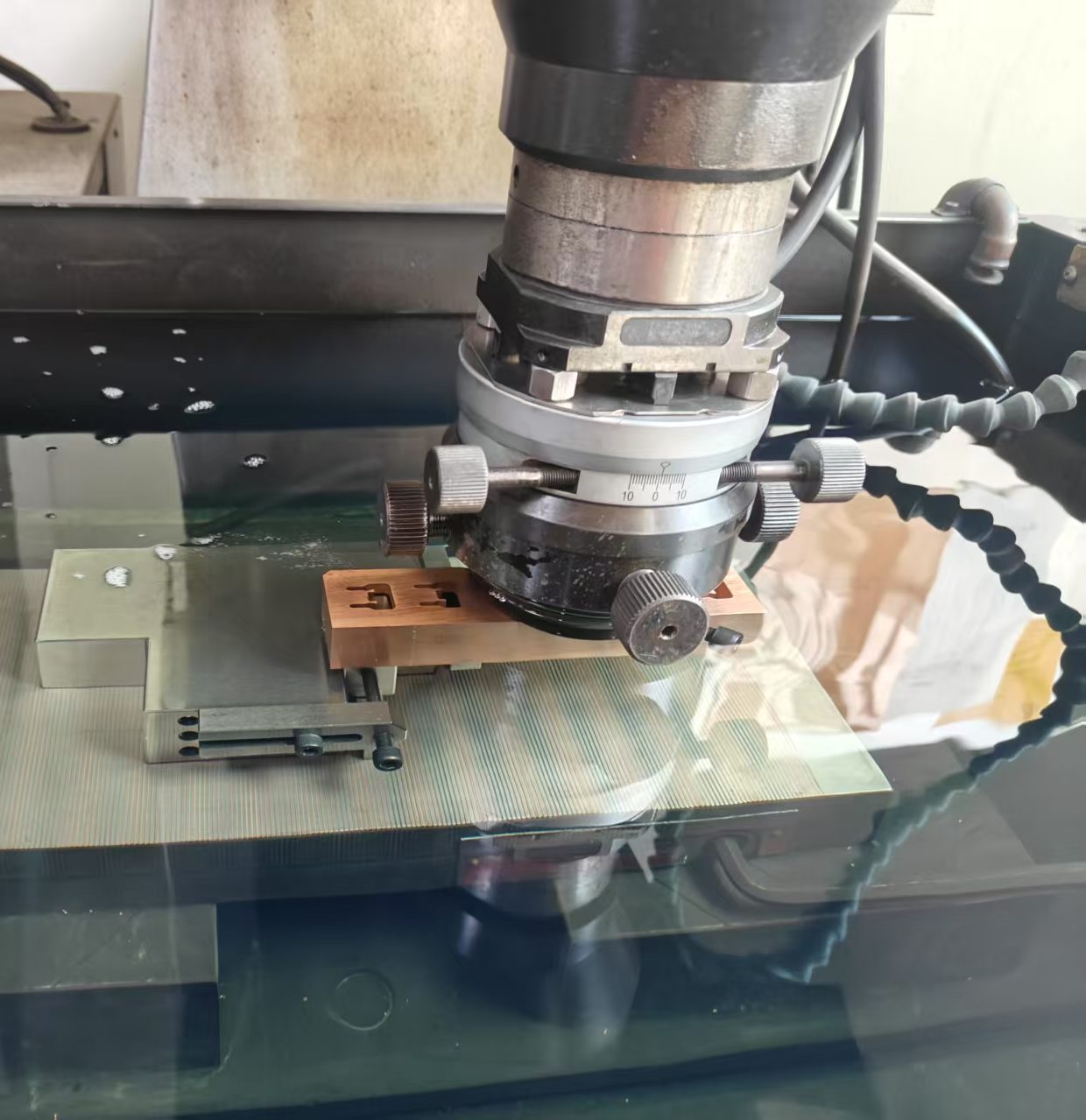

Precision Electrical Discharge Machining Service (Precision EDM)

Precision Electrical Discharge Machining (Precision EDM) is a non-traditional machining process that precisely removes material through instantaneous discharges between the electrode and workpiece in a dielectric medium. It achieves micrometer or even sub-micrometer level accuracy, making it suitable for machining intricate cavities, narrow slots, micro-holes, and other fine structures.

Injection Molding Service

Injection molding is a manufacturing process in which heated and molten thermoplastic or thermosetting materials are injected into a mold cavity under high pressure. The materials cool and solidify within the cavity to form finished parts. Its main advantages include: fast production speed, high efficiency, realizable automated production, suitability for various plastic materials, the ability to form complex shapes, and excellent dimensional accuracy.

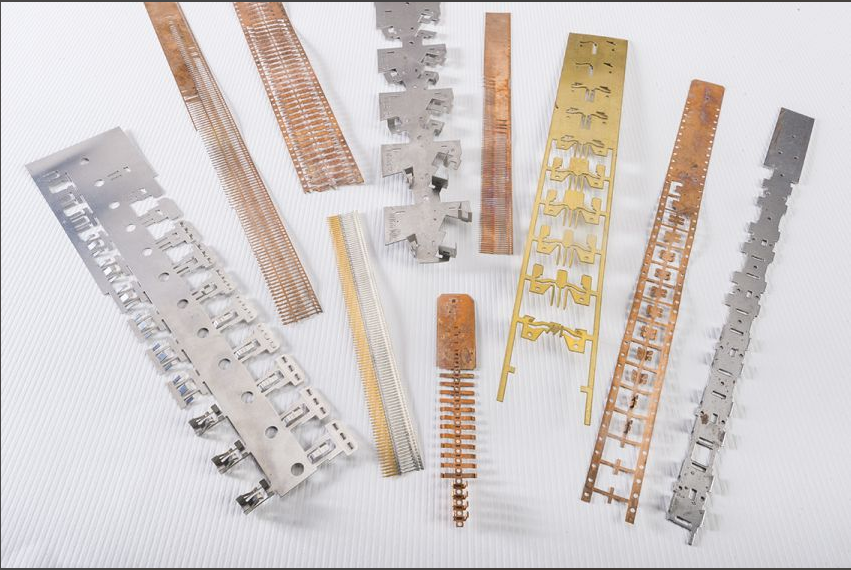

Precision metal stamping products

JUNYU specializes in the design and manufacturing of precision metal stamping products, consistently delivering high-quality, high-precision components with excellent dimensional consistency. Our stamped parts are widely used in industries such as automotive, electronics, telecommunications, medical, aerospace, and home appliances, making them especially suitable for high-volume production needs.

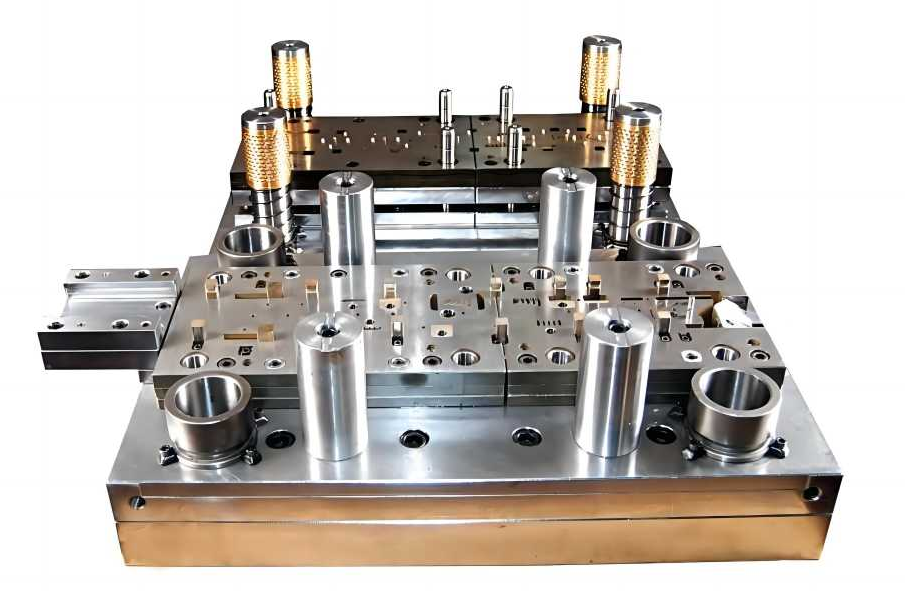

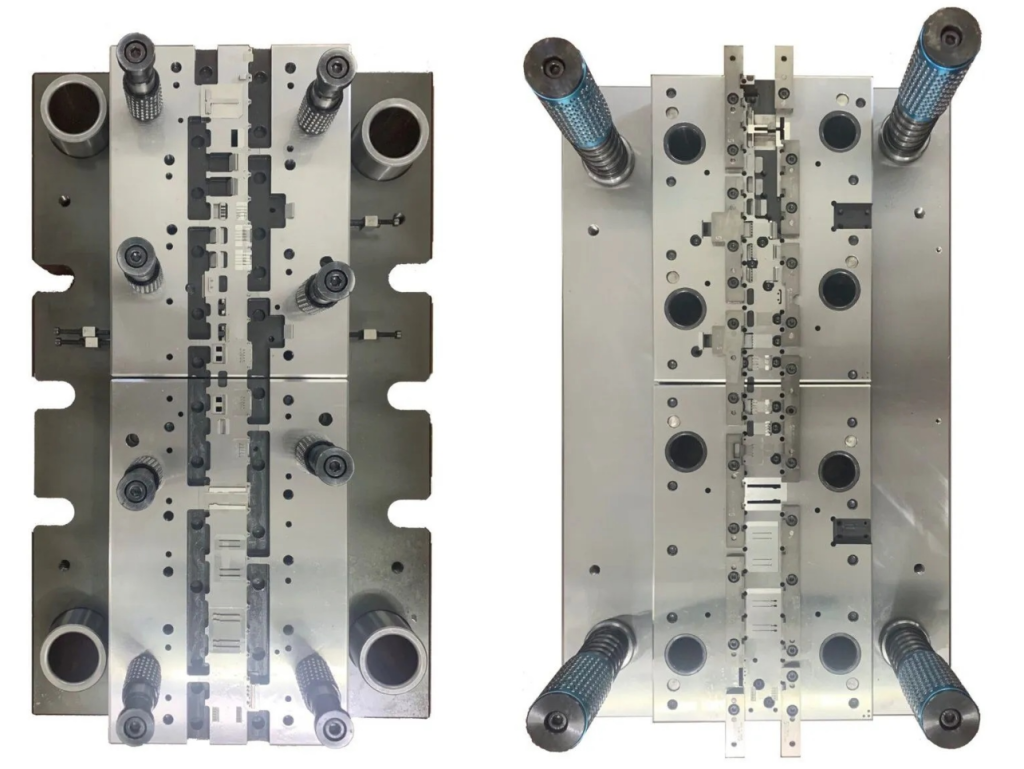

Mold making service

Mold manufacturing refers to the design and machining process of molds that are specifically used for mass production of product components. The main types of molds include injection molds, stamping molds, die-casting molds, blow molds, and extrusion molds. Molds enable the efficient and precise production of large quantities of parts or products with specific shapes and dimensions.

Surface Finishing Service

In addition to product manufacturing, JUNYU offers a wide range of surface finishing solutions to deliver a true one-stop manufacturing experience. From product design to final delivery, our services cover the entire production process, making us the ideal partner to accelerate your project timeline and enhance overall product quality.

Injection Mold Making Service

At JUNYU, an experienced team of Mold-Making specialists works closely with you to research, develop, and deliver the optimal solution for your project. To date, we have assisted thousands of clients in designing precision components that combine exceptional performance, superior manufacturability, and outstanding cost efficiency…

Progressive Die stamping Mold Making Service

A progressive stamping die is a multi-station mold that completes punching, bending, drawing, and other processes sequentially in a single press stroke, enabling high-speed, high-precision, and large-volume production of complex parts. Combined with an automatic feeding system, it improves efficiency and ensures dimensional accuracy. It is widely used in industries such as automotive, electronics, and home appliances, significantly reducing production costs.