Precision Metal Stamping Service

Precision metal stamping is a process of plastically forming metal sheets using high-precision dies and equipment. Its core advantages lie in micron-level accuracy control and scalable mass production capability.

JUNYU is a professional OEM/ODM manufacturer specializing in precision metal stamping. We are proficient in high-speed progressive die stamping and focus on high-volume, high-precision production of various small and complex metal components.

With mature manufacturing techniques and industry-leading technologies, JUNYU provides innovative solutions for your precision stamping projects.

We offer free design consultation, rapid delivery, and a wide range of complementary services including CNC milling, CNC turning, and 3D printing.

Our mission is to deliver a comprehensive one-stop manufacturing solution to meet the diverse needs of our customers.

Our Manufacturing Capabilities

Custom Machining

We provide custom design based on your requirements, offer free professional advice, and complete die preparation in the shortest time to ensure your project starts efficiently.

Precision Manufacturing

We have a professional metal stamping team capable of handling various complex manufacturing challenges, ensuring that every product strictly meets precision standards.

Rapid Delivery

JUNYU is equipped with advanced manufacturing equipment and a professional technical team, enabling us to efficiently handle various complex projects and significantly improve production efficiency. The delivery schedule is arranged flexibly based on project complexity to ensure high-quality and on-time delivery.

Applications of Stamped Metal Parts

Connector

Sensor

New Energy Battery

IC LeadFrame

Telecommunication

Solar Photovoitaic

Medical Electronic

Tact Switch

Automobile Wire Harness

Precision Metal Stamping Parts

From Materials

| Stainless Steel Stamped Parts | Aluminum Stamped Parts | Nickel-Silver Stamping Parts |

| Brass Stamping Parts | Copper Stamping Parts | Spring Steel Stamping Parts |

From Usage

| Spring Electrical Contacts | Deep Drawn Parts | Rivet Contacts |

| Automotive Terminals | Press-fit Terminals / Pins | Flat Spring Clips |

| EMI / RFI Shielding Cans | Micro Lead Frame | Sensor Housings |

Metal Stamping Manufacturing Process

| Progressive Stamping | Prototype Stamping |

| Precision Stamping | Sheet Metal Stamping |

| Deep Draw Stamping | Micro Miniature Stamping |

| Metal Forming | Metal Bending |

| Rivet Stamping |

Types of Metal Stamping

Single-stage Stamping

Each press cycle performs only one operation, such as shearing, punching, or bending. It is suitable for low-volume production or parts with simple structures.

Compound Stamping

Multiple operations (e.g., punching + blanking) are completed simultaneously in a single press stroke. This improves production efficiency and is ideal for parts with moderate complexity.

Progressive Die Stamping

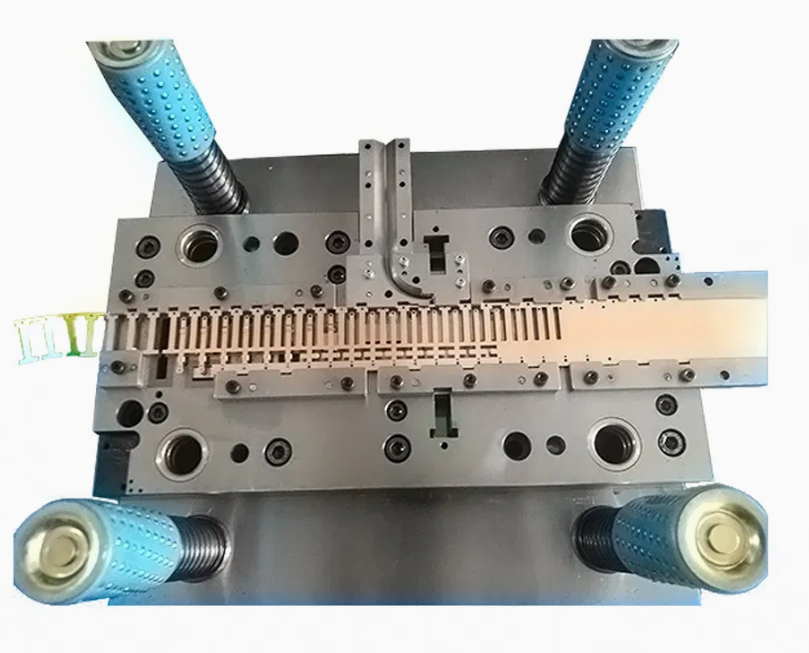

A progressive die is used, and the material moves through multiple stations with each press stroke. This method is well-suited for high-volume production of precision parts.

Deep Drawing

The metal sheet is drawn into a hollow or curved shape, commonly used in producing enclosures and container-type products such as oil pans or cookware.

Transfer Stamping

During stamping, parts are transferred between different stations by mechanical arms. It is ideal for producing complex and intricate parts.

Fine Blanking

A high-precision blanking process that produces smooth edges and accurate dimensions. It is commonly used for precision parts like gears and brake components.

Metal Stamping Design

Metal stamping is a complex manufacturing process that typically involves various metal forming operations such as blanking, punching, and bending.

An excellent stamping design should fully integrate product functionality with the customer’s specific requirements, ensuring an optimal balance between structure, performance, and manufacturing efficiency.

| Methods | Functions |

| Punching | In punching operations, a scrap piece of material is removed as the punch enters the die, effectively leaving a hole in the workpiece. |

| Blanking | removes a workpiece from the primary material, making that removed component the desired workpiece or blank. |

| Embossing | creating either a raised or recessed design in sheet metal, by pressing the raw blank against a die that contains the desired shape, or bypassing the material blank through a roller die. |

| Coning | This action causes the punch tip to penetrate the metal and results in accurate, repeatable bends. |

| Bending | The bending process for metal results in a plastic deformation that stresses above the yield point but below the tensile strength. |

| Flanging | a process of introducing a flare or flange onto a metal workpiece through the use of dies, presses, or specialized flanging machinery. |

Precision Stamping Metal Parts Cases

Terminals

Type-C Terminal

DDR 4.0 Terminal

Fish-eye Terminal

Automotive

Medical

Semiconductor

Communications

Smart Home

Sample Display

Terminal Products

Metal stamping can be used to produce a wide variety of terminal products. Terminals are the core components of connectors, primarily serving to reliably transmit current or signals from one end to the other, ensuring the stable operation of electronic systems.

As a critical subcategory in metal stamping, terminal products are widely used across various industries—especially in electronics, electrical systems, automotive, and telecommunications.

Precision is a key indicator of the quality and performance of terminal products. JUNYU is capable of manufacturing high-precision terminals with tolerances controlled within ±0.01mm. We commonly use materials with excellent conductivity and elasticity, such as copper, phosphor bronze, brass, and stainless steel.

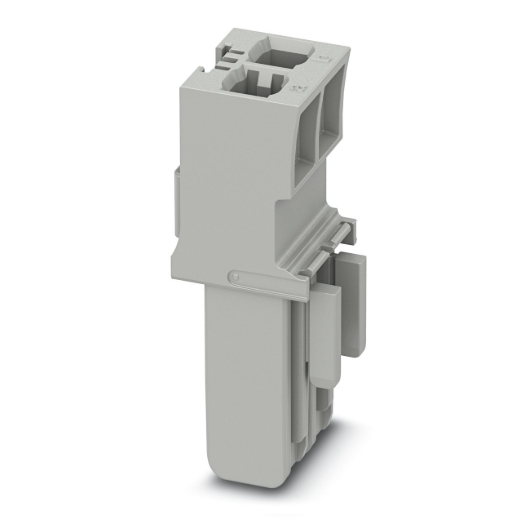

Connector Housing Products

Connector housings are critical structural components in electronic devices, providing electrical shielding, mechanical protection, and secure mating alignment, while also playing a vital role in the overall stability and lifespan of the system.

JUNYU specializes in the custom manufacturing of metal stamped connector housings, integrating high-speed stamping, precision die design, and advanced surface treatment technologies to deliver high-precision and highly reliable product solutions.

We carefully select high-performance materials such as stainless steel, copper alloys, phosphor bronze, beryllium copper, and aluminum alloys, balancing excellent conductivity, formability, and corrosion resistance to meet the requirements of various application scenarios.

In terms of process, we employ progressive die stamping technology, integrating multiple operations such as blanking, punching, and bending within a single die. Tooling precision is controlled within ±0.01 mm, ensuring dimensional consistency and interchangeability in mass production.

JUNYU is equipped with high-speed presses ranging from 45 to 160 tons, combined with automated feeding systems, enabling efficient and stable batch processing of materials from 0.1 mm to 1.5 mm in thickness—fully supporting the production of a wide range of precision connector housings.

Materials For Custom Metal Stamping Service

| Material (EN) | Key Properties | Typical Applications |

| Stainless Steel | High strength, corrosion resistance, heat resistance | Structural housings, shielding covers, wear-resistant parts |

| Copper | Excellent conductivity, good ductility | Electrical contacts, connector terminals |

| Brass | Good conductivity, moderate hardness, corrosion resistance | Pins, terminals, decorative hardware |

| Phosphor Bronze | Excellent elasticity, fatigue resistance, corrosion resistance | Springs, contact parts, high-frequency terminals |

| Beryllium Copper | High elasticity, strength, and conductivity | High-frequency terminals, high-end connectors |

| Aluminum Alloy | Lightweight, corrosion-resistant, easy to form | Housings, heat sinks, precision structural parts |

| Plated Steel Sheet | Good surface finish, cost-effective | Mid- to low-end structures, protective covers |

Tolerance of Metal Stamping

Common Tolerance Guidelines (Reference Values):

| Feature Type | Recommended Tolerance (Imperial) | Recommended Tolerance (Metric) |

| Hole Diameter | ±0.005″ | ±0.13 mm |

| Bend Radius | ±0.100″ | ±2.54 mm |

| Outer Dimensions | ±0.005″ | ±0.13 mm |

| Holes Within Pattern | ±0.005″ | ±0.13 mm |

| Cut Features to Bend | ±0.010″ | ±0.25 mm |

| Bending Angles | ±1° | ±1° |

| Material Thickness | ±0.002″ | ±0.05 mm |

Why Choose Us?

Choosing our metal stamping services means gaining differentiated value through key advantages in precision, cost-efficiency, quality, and material capability.

1.High Precision

We utilize advanced progressive dies, high-speed presses, and automated feeding systems. Tolerances are controlled within ±0.01 mm, ensuring consistent quality even for complex geometries and high-precision requirements.

2.Cost & Efficiency Optimization

Economical Tolerance Strategy: We apply function-based tolerance grading—critical assembly dimensions are held tight (±0.1 mm), while non-functional features are relaxed (±0.3 mm), avoiding unnecessary costs from overly strict standards.

This approach helps reduce tooling costs by 15%–30% compared to industry averages.

3.Wide Material Capability

We process a wide range of metals, including stainless steel, phosphor bronze, brass, beryllium copper, and aluminum alloys—balancing conductivity, formability, and corrosion resistance. Multiple surface finishing options are available, such as gold plating, tin plating, nickel plating, and PVD coating.

4.Strict Quality Control

Equipped with CMMs, vision inspection systems, and CCD detectors, we ensure every product shipped meets the highest quality standards.

Common Questions

If you have any questions, feel free to contact us — we’ll get back to you as soon as possible.

What the best lead time for micro precision stamped metal parts?

For first-time tooling development projects, the FAI (First Article Inspection) sample can be completed within 30 days after receiving the deposit.

Once the sample is approved by the customer and raw materials are ready, mass production can be completed and delivered within 15 days

Can you meet the required stamping speed?

Yes, we can. The tooling speed is closely related to the component’s structure.

We take factors such as strip thickness and the number of bending stations into consideration to determine an optimal speed that ensures stable and efficient production

Can you provide 3D design?

Yes, we can provide 3D designs for both parts and tooling.

How do you control the quality of stamping parts?

1.Production is carried out according to the stamping SOP, with each tooling having its own specific SOP.

2.Measurements are taken in accordance with the Inspection SOP, including sampling times and inspection methods, all following SOP guidelines.

3.Packing is performed following the Packing SOP.

4.OQC (Outgoing Quality Control) follows the OQC SOP.

Each process is tracked with reports, from raw materials to finished components. Parts can also be traced by lot number.

Is your production capacity sufficient to support this project?

JUNYU has 36 sets of high-speed presses, with the current production capacity at 60%, which is sufficient to handle our project.

After reviewing the drawing requirements, we have confirmed that our tooling capabilities are adequate for the job.

Our process control systems are capable of meeting the demands of this project.

How can you maintain stable quality?

1.Raw materials are sourced from certified brand suppliers, ensuring consistent and reliable quality.

2.Surface treatments are carried out by qualified and approved suppliers.

3.Supplier management is conducted in accordance with JUNYU’s internal supplier control procedures.

4.Production is strictly performed following internal Standard Operating Procedures (SOPs).

How do you guarantee on-time delivery?

1.Upon receiving the purchase order (PO), our PMC (Production and Material Control) team will promptly confirm the delivery schedule and closely monitor the progress.

2.Tooling condition is thoroughly checked to ensure it is ready and qualified for production.

3.Raw materials and accessories are purchased according to the project BOM (Bill of Materials) to ensure timely readiness.

4.Production and quality control are carried out strictly in accordance with internal SOPs.

5.A dedicated project team oversees the workflow, with delivery performance managed through KPI tracking.

Try JUNYU Out Now In Just A Few Steps

Upload your 2D/3D files

Simply upload your project files—our engineering team will review them and deliver a customized solution promptly.

Your Order Get Started

As long as we receive your confirmation, we will start your project immediately.

Receive Your Order

Your custom machined parts will be delivered right to your doorstep

Ready to place your order? Fill out the form below to get in touch with us!